-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

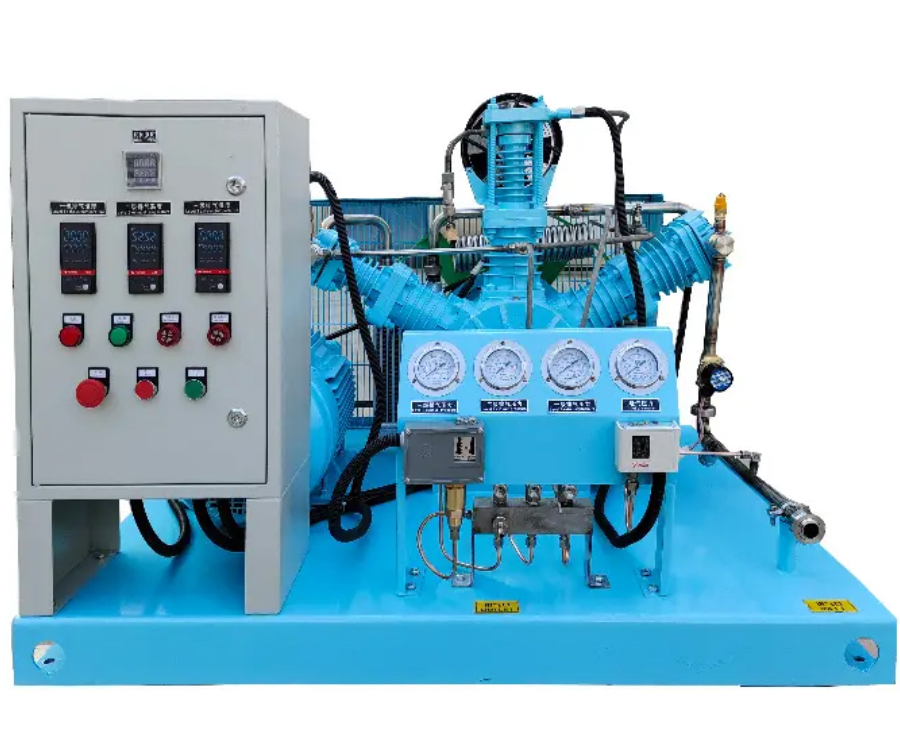

Our professionally engineered oxygen compressors offer complete customization, ensuring a perfect match for your specific working conditions. With exceptional oil-free technology, reliable performance, and cost-effectiveness, our compressors have become the ideal choice for global industrial, medical, and specialized applications.

Single-Stage Compression: For basic boosting requirements

Multi-Stage Compression Systems: Two-stage, three-stage, and four-stage configurations available to meet different pressure needs

Custom Engineering Consultation: Our technical team analyzes your working conditions to recommend the optimal compression solution

Motor Systems: Can specify international brands like Siemens, ABB, and others

Critical Components: Select component suppliers based on your quality preferences and regional requirements

Special Certifications: Configurable with components and complete units that meet high-standard requirements like those of the Japanese market

Optimized design based on your specific pressure, flow rate, and purity requirements

Compatible with VPSA/PSA oxygen sources and other oxygen supply systems

Customized for different application scenarios: medical, industrial, laboratory, etc.

Stainless Steel Cylinders: Completely oil-free design eliminates contamination risk

Purity Preservation: Compression process maintains 100% gas composition integrity

Certified Materials: All gas-contact materials comply with medical/industrial gas standards

Extended-Life Piston Rings:

Low-pressure conditions: Up to 4,000 hours service life

High-pressure conditions: 1,500-2,000 hours service life

Low-Speed Operation: 260-400 RPM average speed reduces wear

Heavy-Duty Continuous Operation: Supports 24/7 uninterrupted operation (model-dependent)

Low-Noise Operation: Average noise level <75 dB, suitable for medical environments and quiet spaces

High-Efficiency Design: Optimized compression ratio and thermal management reduce operating costs

Easy Maintenance: Modular design minimizes downtime and maintenance costs

Multiple Safety Protections: Over-pressure, over-temperature, and overload protection systems

Rigorous Testing: Each unit undergoes 72-hour continuous operation testing before shipment

International Compliance: Meets CE, ISO, and other relevant international standards

Lower Acquisition Costs: 30-50% savings compared to similar international brands

Reduced Maintenance Expenses: Durable design and easy-maintenance structure lower lifecycle costs

Simple Operation: User-friendly interface reduces training needs and operational errors

Can be designed to match your existing systems

Compatible with most international brand interfaces and installation requirements

Seamless replacement of aging or inefficient equipment without modifying existing infrastructure

Japanese Market Supply: Meets some of the world's most stringent quality requirements

Multi-Industry Applications: Successfully deployed in medical, water treatment, metal fabrication, chemical, and other industries

Proven Reliability Track Record: Validated by thousands of units operating stably worldwide

Requirements Analysis: Share your specific working conditions, pressure requirements, flow needs, and space constraints

Solution Design: Our engineering team provides 2-3 optimized design proposals

Component Selection: Jointly determine motor brands, control systems, and other critical components

Production & Testing: Custom manufacturing followed by rigorous performance and safety testing

Delivery & Support: Global logistics arrangement and installation technical support

| Parameter | Specification Range |

|---|---|

| Compression Stages | Single, Two, Three, Four (Customizable) |

| Motor Options | Siemens, ABB, or specified brands |

| Operating Speed | 260-400 RPM (Adjustable) |

| Noise Level | <75 dB(A) |

| Continuous Operation | 24/7 (Depending on configuration) |

| Piston Ring Life | Low Pressure: 4,000 hrs; High Pressure: 1,500-2,000 hrs |

| Material Standards | Stainless steel cylinders, oil-free design |

| Compatible Gases | Oxygen (VPSA/PSA source compatible) |

Medical Oxygen Supply Systems: Hospitals, clinics, home care

Industrial Applications: Metal cutting, welding, chemical processes

Water Treatment: Ozone generation system boosting

Laboratories & Research: High-purity oxygen supply

PSA/VPSA Systems: Oxygen source boosting and delivery

Contact us for personalized quotation and design consultation

Provide your specific operating parameters and needs

Receive targeted compressor configuration proposals

Obtain detailed technical specifications and quotation

Parameter table of conventional reciprocating oilless oxygen booster

| model | working medium | Intake pressure. barg | Exhaust pressure.barg | Nominal volumetric flow rate NM3/hour | Motor power (KW) | voltage frequency | Intake/ exhaust port.mm | Cooling method | Net weight (kg) | Size (mm) | Compression levels |

| GOW-4/4-150 | oxygen | 3-4 | 150 | 4 | 3 | 380/50/3 | DN15/DN6 | air-cooled | 320 | 1000×750×1050 | Level 4 |

| GOW-5/4-150 | oxygen | 3-4 | 150 | 5 | 3 | 380/50/3 | DN15/DN6 | air-cooled | 320 | 1000×750×1050 | Level 4 |

| GOW-6/4-150 | oxygen | 3-4 | 150 | 6 | 3 | 380/50/3 | DN15/DN6 | air-cooled | 320 | 1000×750×1050 | Level 4 |

| GOW-8/4-150 | oxygen | 3-4 | 150 | 8 | 4 | 380/50/3 | DN15/DN6 | air-cooled | 330 | 1000×750×1050 | Level 4 |

| GOW-10/4-150 | oxygen | 3-4 | 150 | 10 | 5.5 | 380/50/3 | DN15/DN6 | air-cooled | 340 | 1000×750×1050 | Level 4 |

| GOW-12/4- |