-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

![[list:title]](https://www.hc986.com/static/upload/image/20260114/1768359597182851.jpg)

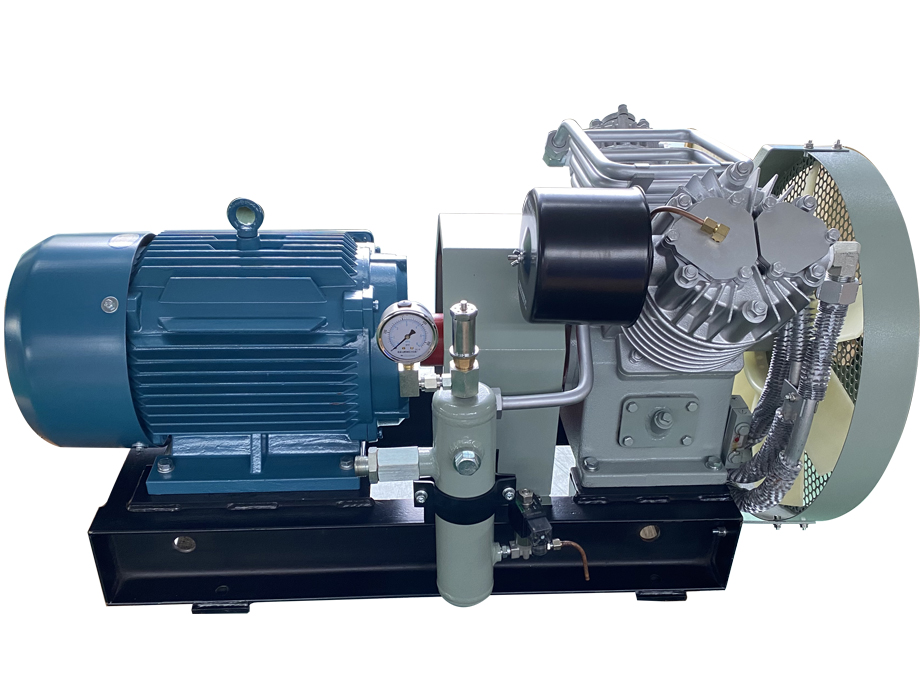

HCV-40/30F Marine Air Compressor

HCV-40/30F Marine Air Compressor

Product Overview

The HCV-40/30F marine air compressor is a medium-pressure air compressor designed for marine environments. It is suitable for marine engine starting, pneumatic tools, and various marine systems that require compressed air.

Technical parameters

Project: Parameters

Displacement: 40 m³/h

Working pressure: 3.0 MPa

Motor power: 11 KW

Rotational speed: 970 r/min

Electricity: 380V, 50/60 Hz

Transmission method: direct drive

Net weight: 270 KG

External dimensions: 1135 × 610 × 640 mm

Lubrication method: Splash lubrication

Ship applicability characteristics

Corrosion-resistant design

Since ships are in a marine environment for extended periods, the internal components of the machine that come into contact with compressed air are made of stainless steel, copper alloys, or have undergone anti-corrosion treatment to cope with seawater salinity and humid climate.

Environmental adaptability

It can adapt to complex sea conditions and climate conditions such as high temperature, high humidity, and strong winds and waves during ship navigation. The seals and materials have high and low temperature resistance to ensure normal operation in different temperature environments.

Stress adaptability

Shipboard equipment has varying requirements for compressed air pressure. This machine is equipped with a pressure regulation system, which can adjust the pressure according to actual usage requirements.

Continuous operation capability

To meet the equipment requirements of ships that rely on compressed air during long voyages, this machine uses standard components and manufacturing processes, and has been tested and inspected to support stable operation over long periods.

Compact structure

Its compact design, small size, and light weight make it easy to install in confined spaces such as ship engine rooms, minimizing its impact on the ship's center of gravity and stability.

Usage Recommendations

Considering the role of air compressors in ship operation, it is recommended that users equip themselves with backup air compressors according to actual conditions, so as to switch them in case of main air compressor failure or maintenance, and ensure the normal operation of the ship.

The above information is for reference only. Please refer to the equipment manual and the actual operating conditions of the vessel for specific usage.

Features:

Corrosion Resistance: Since ships operate in the marine environment for extended periods, marine air compressors require excellent corrosion resistance. Internal components in contact with compressed air are typically made of special anti-corrosion materials or undergo anti-corrosion treatments, such as using stainless steel or copper alloys, to prevent corrosion caused by seawater salt and humid climates, thus extending the equipment's service life.

Adapting to complex environments: Ships face various complex sea conditions and climates during navigation, such as high temperatures, high humidity, and strong winds and waves. Marine air compressors need to be able to operate stably in such environments. Therefore, their design takes these factors into account and has good environmental adaptability. For example, they use high-temperature and low-temperature resistant materials and seals to ensure normal operation under different temperature conditions.

To meet varying pressure requirements: Different equipment and systems on board have different compressed air pressure requirements. For example, starting a ship's engine generally requires higher pressure, while some pneumatic tools may only require lower pressure. Marine air compressors need to be able to meet these different pressure requirements and are usually equipped with multi-stage compression devices or pressure regulating systems, which can adjust the pressure according to actual needs.

Continuous Operation Capability: When ships are at sea, many devices rely on compressed air for operation; therefore, marine air compressors need to be capable of continuous operation for extended periods. Their design and manufacturing must ensure stable performance and prevent frequent malfunctions during long-term operation. To improve reliability, our marine air compressors typically utilize high-quality components and advanced manufacturing processes, and undergo rigorous testing and inspection.

Backup System: Considering the importance of air compressors in ship operation, and to prevent the ship from losing power or other critical functions due to air compressor failure, our company recommends that ships be equipped with a backup marine air compressor. When the main air compressor fails or requires maintenance, the backup air compressor can be started in time to ensure the normal operation of the ship.

4. Compactness: Space is precious on ships, and marine air compressors need to be installed and arranged within limited space. Therefore, our marine air compressors are typically designed to be compact, small in size, and lightweight, facilitating installation in the ship's engine room or other suitable locations. At the same time, the compact design also helps reduce the air compressor's impact on the ship's center of gravity and stability.

In summary, the characteristics of our marine air compressors include corrosion resistance, adaptability, reliability, safety, and compactness. These characteristics enable our marine air compressors to operate stably in harsh marine environments, providing reliable compressed air support for various equipment and systems on ships, ensuring safe navigation and normal operation.

View more pictures. Quickly select and customize marine air compressors based on parameters.