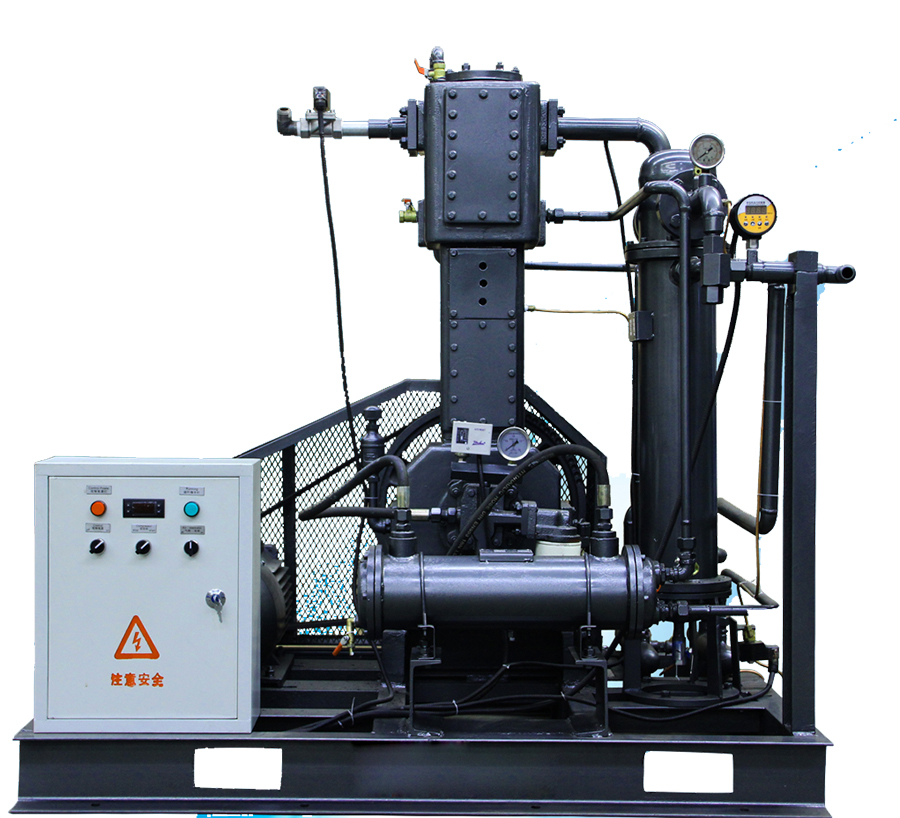

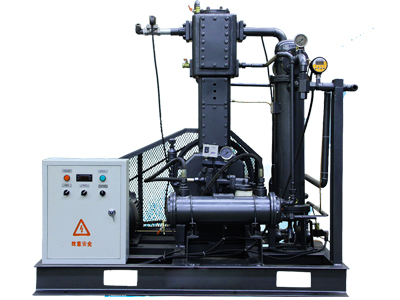

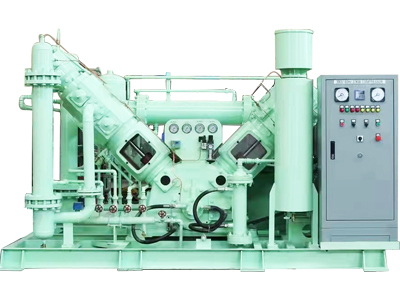

Product description:

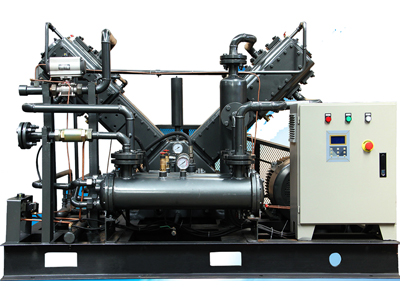

The oil-free supercharger produced by our company has the characteristics of stable operation, low failure rate, convenient maintenance, low maintenance cost, oil-free lubrication of the gas contact part, and clean gas after pressure, and has been highly praised by customers. The unit adopts water cooling to ensure the continuous operation of the machine at low temperature for a long time, and the PLC program is used to control and monitor the operation of the equipment to achieve unattended, fault alarm and shutdown. All supporting parts are made of domestic famous brands, and the core parts of the main machine are made of exclusive formula and standard process, so as to ensure the durability of the machine and greatly improve the service life of the whole machine. It is mainly used for PET bottle blowing, filling machine air supply, nitrogen pressurization and users with large gas consumption.

Main scope of supply:

Booster host

High efficiency drive motor

drive system

circulatory system

Control system

Safety devices

Alarm device

cooling system

Stand

Documents (including operation manual and parts manual)

Component composition and principle of booster engine:

1. Crankcase components

The crankcase is equipped with an oil sight glass, a respirator, a gear oil pump, and an oil filter screen at the bottom of the crankcase

2. Crankshaft, connecting rod and components

The crank of the crankshaft is equipped with a connecting rod. Both ends of the crankshaft are equipped with rolling bearings. The big end of the crankshaft is equipped with a pulley for rotation. The lubrication of the crankshaft is to install a gear cooling oil pump to the crankshaft and crosshead pin

3. Guide cylinder components

The guide cylinder is equipped with crosshead, crosshead pin and oil ring to separate the oil from the cylinder

4. Cylinder components

The cylinder is equipped with water inlet and outlet respectively. Water is added to circulate in the cylinder. Air inlet and exhaust valves are installed on both sides of the cylinder. Piston and piston rod are installed inside the cylinder. The piston rod is connected with crosshead screws. The bottom of the cylinder is equipped with a packing seal

5. Piston parts

Two sets of piston components, the piston is aluminum alloy, and the piston is equipped with oil-free piston ring and backup ring

6. Air inlet and exhaust valve

The intake and exhaust valves are steel parts and combination valves

7. Pipeline

The primary and secondary air inlets and outlets are welded with stainless steel pipes, and the primary and secondary pipes have safety valve pressure

Force sensor and temperature sensor

8. Cooler components

The cooler is divided into oil cooler and primary and secondary air coolers, which are divided into three groups. The water pump enters the cooler interface for cooling, and the outlet of the water pump is equipped with a water pressure sensor

Control system:

1. Control cabinet is installed on the main unit

2. There is an intelligent controller on the control cabinet panel

3. The booster inlet is equipped with an automatic loading and unloading valve

4. The booster's secondary air inlet is equipped with an oil-water separator for automatic drainage

5. The booster is equipped with an emptying valve. When the pressure reaches the rated pressure, it will be drained automatically to make the booster run with no load

6. The first and second stages are equipped with temperature sensors. If the temperature is too high, it will automatically alarm and shut down

7. The first and second stages are equipped with pressure sensors. If the pressure of the first and second stages exceeds the set pressure, it will automatically alarm and shut down

8. The water pressure sensor will automatically alarm and shut down when it is lower than the set pressure

9. The oil pressure sensor will automatically alarm and shut down when it is lower than the set pressure

Standard technical standards for design and manufacturing:

GB699 Technical Requirements for High Quality Carbon Structural Steel

GB1031 Surface Roughness Parameters and Their Values

GB1173 Technical Conditions for Cast Aluminum Alloys

GB1184 Form and Position Tolerances - Specification for Undeclared Tolerances

GB1801 Tolerances and Fits

GB3077 Specification for Alloy Structural Steel

GB9438 Technical Conditions for Aluminum Alloy

GB9439 Standard 250 for gray cast iron of medium pressure cylinder

JB2230 Shaft pin outer diameter of reciprocating piston compressor

JB2231 Cylinder diameter of reciprocating piston compressor

JB/T6431 Technical Conditions of Grey Cast Iron for Displacement Compressors

JB/T6908 Technical Conditions for Forgings of Displacement Compressor

ZBJ72 016 Technical Conditions of Ductile Iron Castings for Volumetric Compressors

ZBJ72 025 Terminology of Reciprocating Compressor

GB7777 Measurement and Evaluation of Mechanical Vibration of Reciprocating Piston Compressors

GB151 Aluminum Shell and Tube Heat Exchanger