-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

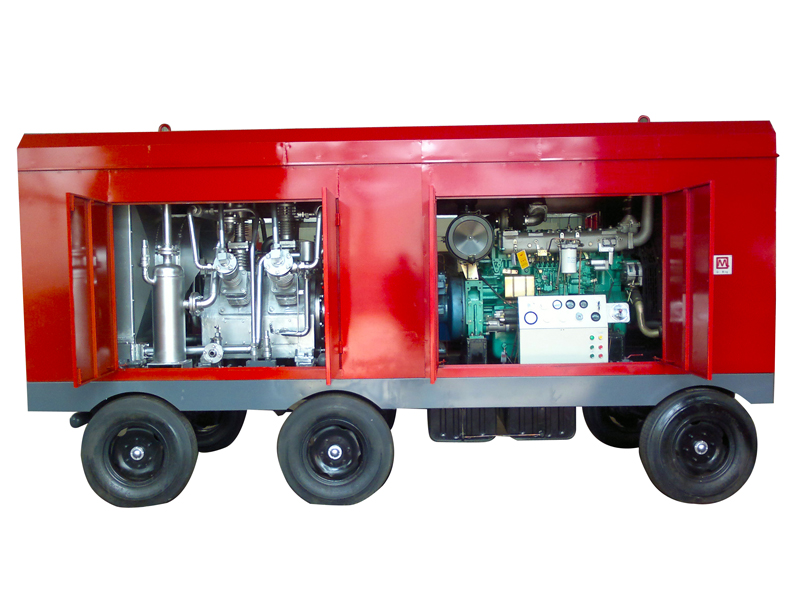

Русский язык

I. Main Technical Parameters of the Compressor

1. Medium composition: air

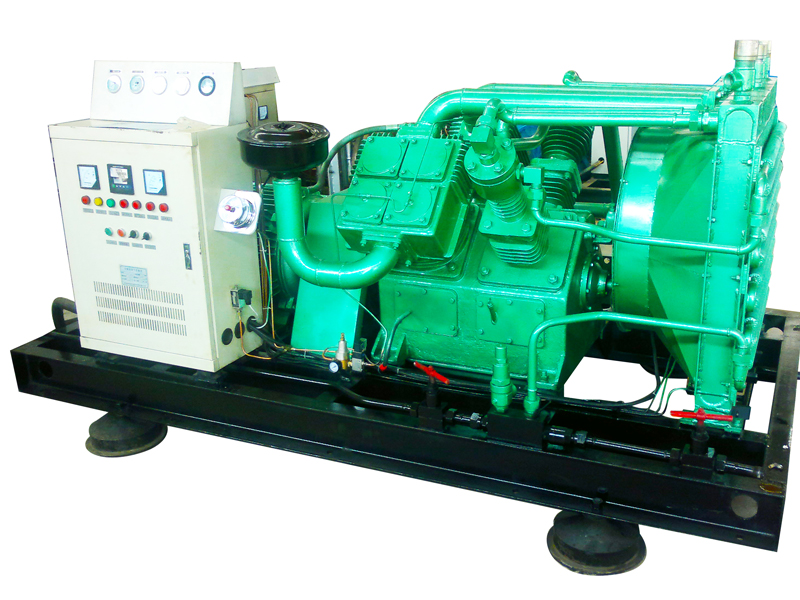

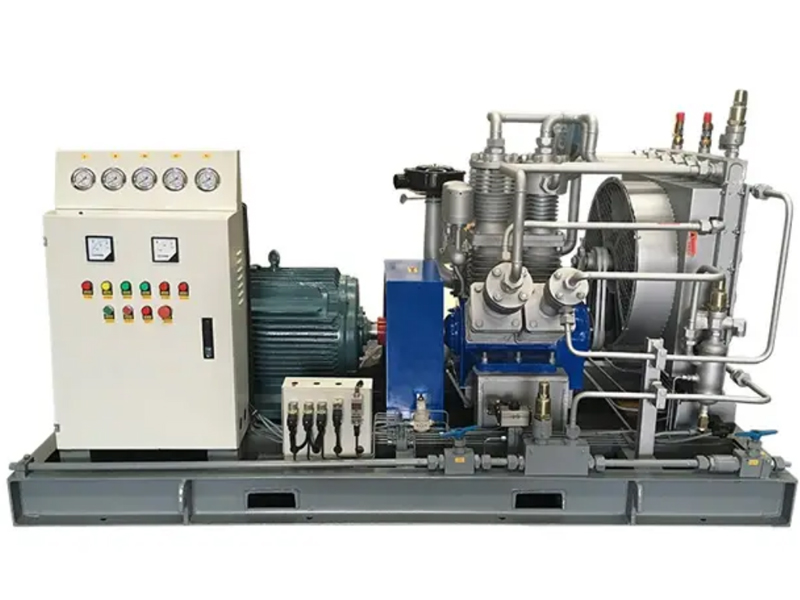

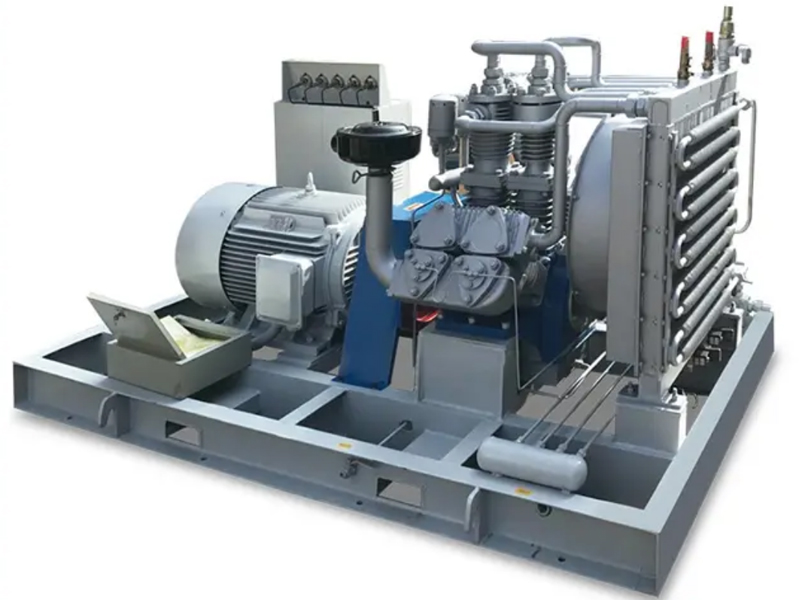

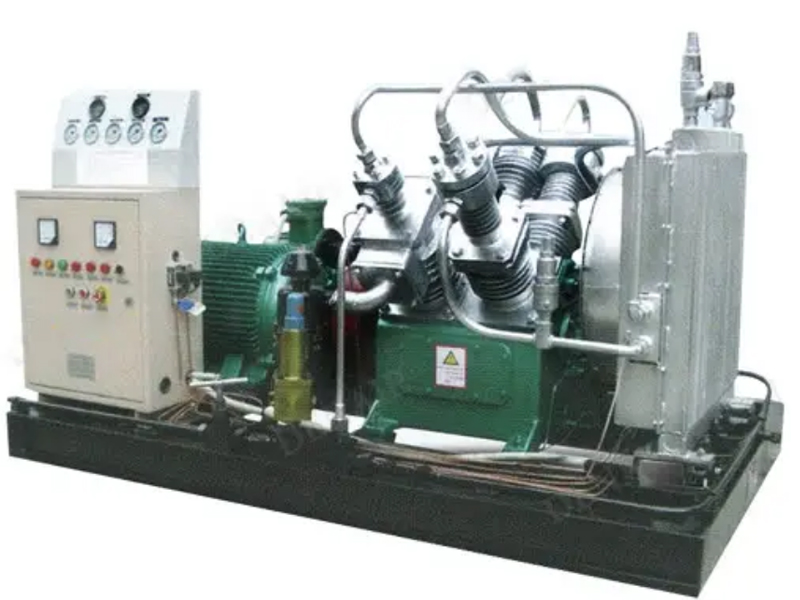

2. Compressor Model: VF-1/350 Direct-Drive High-Pressure Air Compressor

3. Structural form: V-shaped, air-cooled

4. Compression stages: Four-stage compression

5. Cylinder diameter for each grade (mm): Grade 1 Φ170, Grade 2 Φ80, Grade 3 Φ60, Grade 4 Φ30, Grade 5 Φ18

6. Nominal volumetric flow rate (m³/min): 1

7. Inhalation pressure: MPa(G): Atmospheric pressure

8. Exhaust pressure: MPa(G): 0.35.0

9. Inhalation temperature (°C): ≤40

10. Gas supply temperature (°C): ≤60 (after post-cooling)

11. Compressor speed (r/min): 740

12. Transmission method: Direct connection with flexible coupling

13. Lubrication method: Splash lubrication

14. Installation method: Requires a foundation.

15. Lubricating oil consumption: 42g/h

16. Noise dB(A): ≤90

17. Powertrain: Y-225M-8 22 KW 740r/min

18. Stroke: 110mm

19. External dimensions (length × width × height) mm: Approximately 2200 × 1400 × 1400

20. Weight (kg): Approximately 2000

II. Compressor Main Unit

1. Crankcase components:

The crankcase has side covers and oil sight glasses on both sides for disassembly and inspection. The front section, which is the power connection end, is equipped with a bearing housing and a front bearing cover. The fan bracket on the upper part of the rear bearing cover supports the fan assembly. The upper part is cast with cylinder support planes at 90 degrees to each other. The larger side is equipped with the first-stage cylinder assembly, and the smaller side is equipped with the second-stage cylinder assembly. The top surface is equipped with a breather. The bottom of the crankcase is equipped with an oil pan, which contains special compressor oil.

2. Crankshaft, connecting rod and components

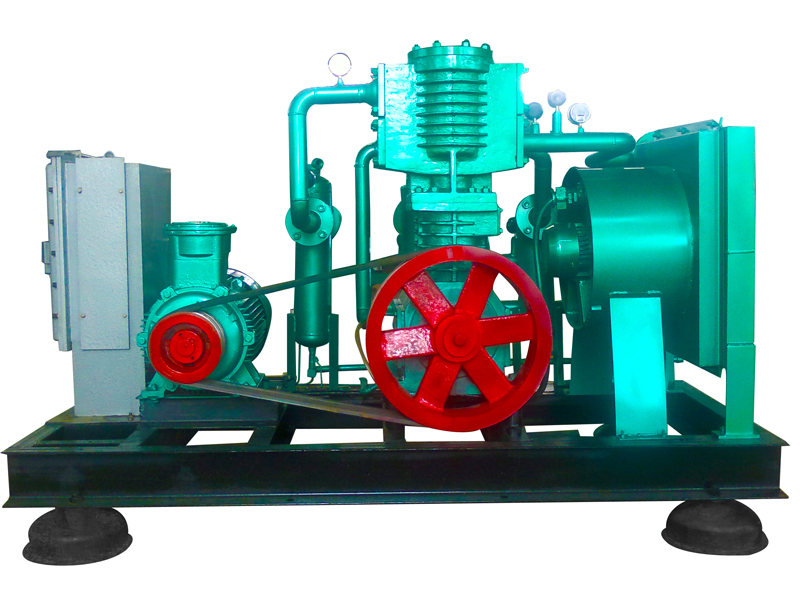

The crankshaft has a connecting rod mounted on the crankshaft crankpin, and rolling bearings (22315) at both ends. A flywheel connected to a flexible coupling is mounted on the large end of the crankshaft; a pulley is mounted on the small end near the bearing to drive the cooling fan. The crankshaft is lubricated by oil splashed from the connecting rod's oil rod onto the crankshaft and piston pins, among other components.

3. Piston assembly:

The piston assembly is divided into five stages: primary, secondary, tertiary, quaternary, and quinary. Primary pistons are made of cast aluminum alloy, secondary and tertiary pistons are also made of cast aluminum alloy, while quaternary and quinary pistons are made of steel. Primary pistons are equipped with piston rings: a flat ring at the top, a torsion ring in the middle, and an oil ring at the bottom. The oil scraper ring opening is offset from the piston pin hole by more than 60 degrees, and the openings of each piston ring are offset from each other by 120 degrees. Secondary and tertiary pistons have 7 flat rings, quaternary pistons have 9 flat rings, and quinary pistons have 22 flat rings.

4. Cylinder components:

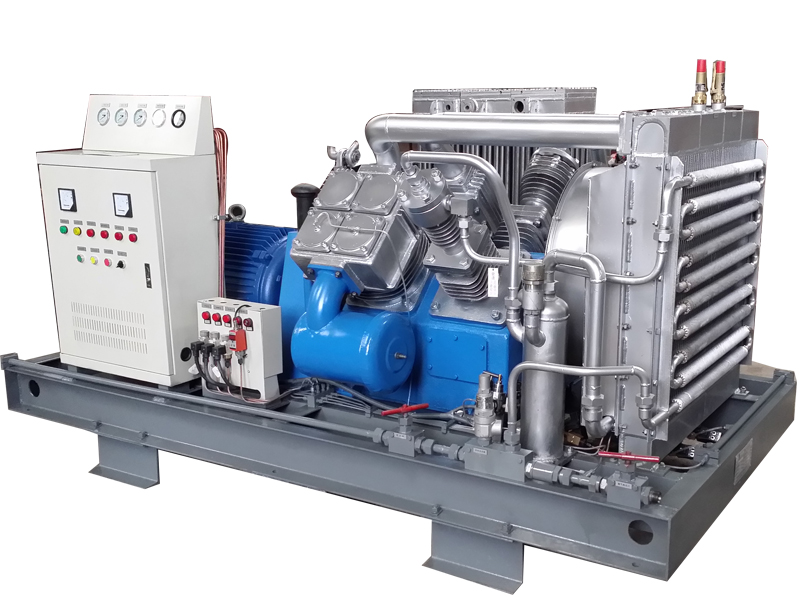

The cylinder components are divided into first-stage, second-stage, third-stage, fourth-stage, and fifth-stage cylinders. The cylinder heads of the first-stage, second-stage, third-stage, fourth-stage, and fifth-stage cylinders are all cast with cooling fins to increase the heat dissipation area. The cylinder heads are equipped with intake and exhaust valve components, intake and exhaust pressure cylinders, and intake and exhaust pressure caps, respectively.

5. Intake and exhaust valve components:

The system consists of a primary intake valve, a primary exhaust valve, a secondary intake valve, and a secondary exhaust valve, all of which are annular valve structures. The valve seat has a spring supporting the annular valve plate, and both the valve plate and the spring are made of high-quality steel. The tertiary and quaternary stages are combined intake and exhaust valves.

6. Cooler and fan components:

It consists of four stages of coolers and a cooling fan. It connects between the inlet and outlet ports of the compressor's first, second, third, and fourth stages. It is mounted on a base by uprights. The cooler has a safety valve at the top and a drain valve at the bottom. A guide cover and protective cover are installed facing the crankcase. A fan-type cooling fan is installed in the middle, and a fan bracket mounts the fan assembly onto the crankcase. The fan is driven by a crankshaft pulley at the end of the crankcase via a V-belt.

III. Compressor Control System

1. The instrument panel is equipped with pressure gauges of levels one, two, three, four, and five, and a compressor oil temperature gauge.

2. The compressor will automatically shut down when the discharge pressure is high, triggering an alarm.

3. The compressor will automatically alarm and shut down when the oil level is low.

4. Lubrication system: The air compressor uses splash lubrication, where oil splashes everywhere in the housing and forms an oil mist, providing good lubrication for bearings, pistons, piston rings and other moving parts.