-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

I. Main Technical Parameters of the Compressor

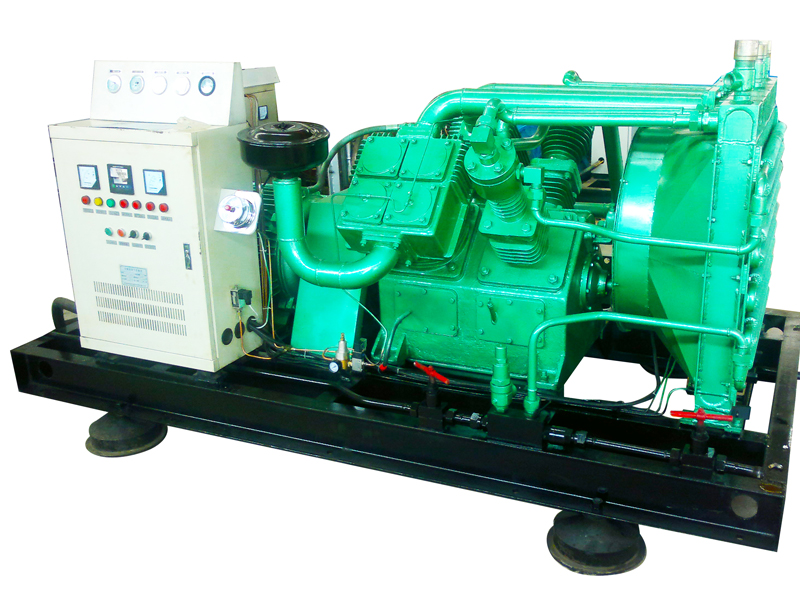

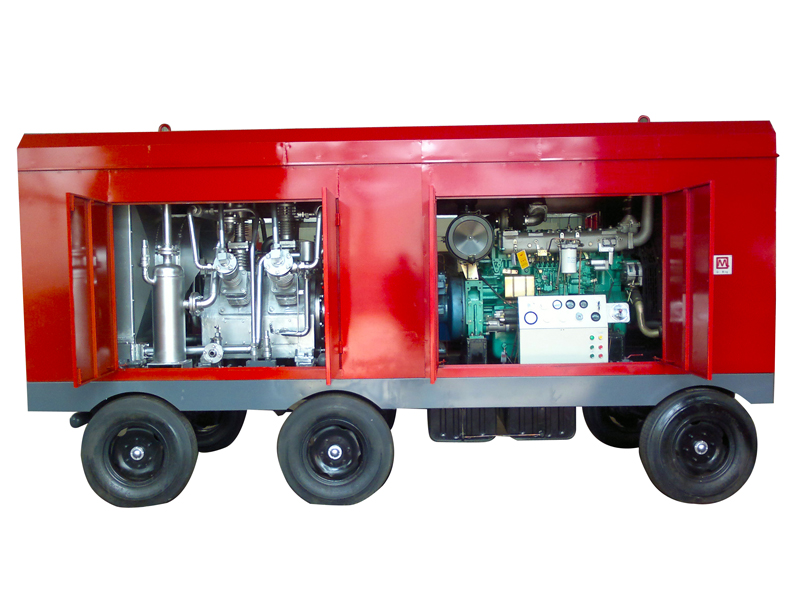

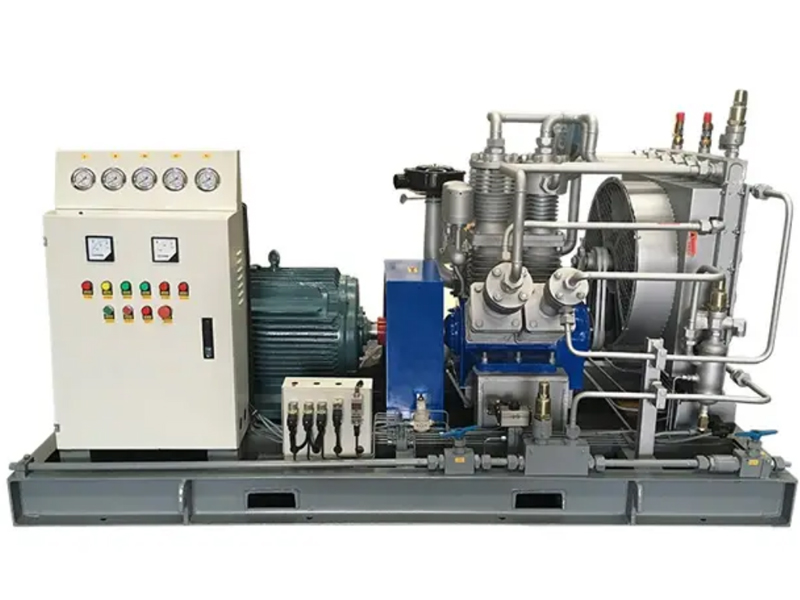

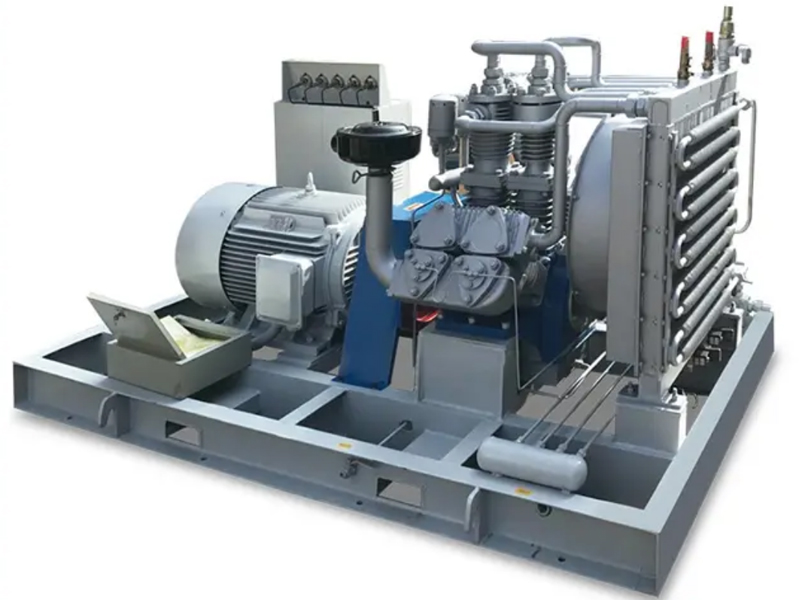

1. Compressor Model: V-7/250 Water-cooled Direct-coupled High-Pressure Air Compressor

2. Compressor type: V-type, reciprocating piston, water-cooled, micro-oil lubricated, fixed installation.

3. Compression medium: air

4. Rated exhaust volume: 7 m³/min

5. Intake pressure: Atmospheric pressure

6. Exhaust pressure: 25 MPa (G)

7. Intake air temperature: 45℃

8. Exhaust temperature: ≤200℃

9. Gas supply temperature: ≤45℃

10. Shaft power: 124kW

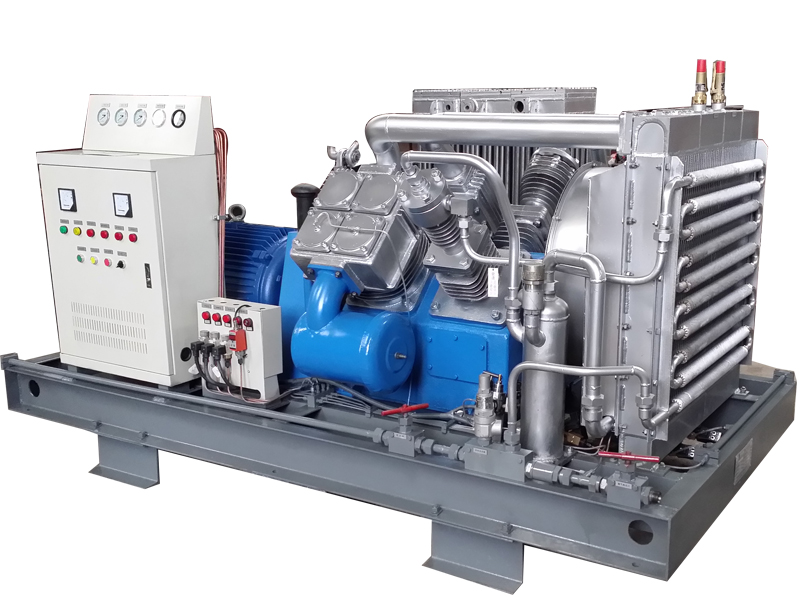

11. Compression levels: Four levels

12. Number of compressor rows: Four rows

13. Cooling method: Water cooling

14. Lubrication method: Pressure lubrication for moving parts, oil-free lubrication for cylinders.

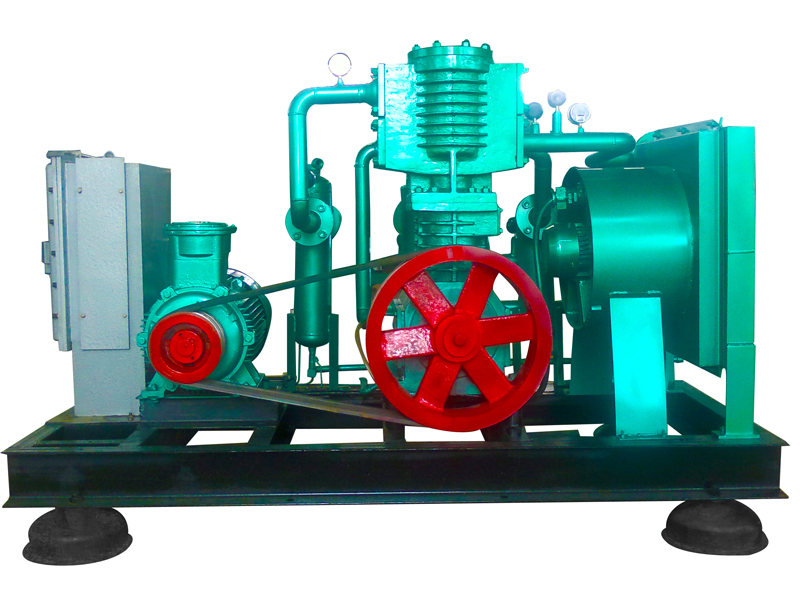

15. Transmission method: Direct connection with flexible coupling

16. Cooling water consumption: 20 m³/h

17. Drive type: Y355S-8 132kW B3 730r/min

18. Rotational speed: 730 r/min

19. Itinerary: 92

20. External dimensions: 4500×2200×1600

21. Weight: ~6000kg

II. Compressor Main Unit

Designed and manufactured using professional technology from the German company "MAINESMANNDEMAG".

1. The crankcase material is HT250.

2. The crankshaft is made of No. 45 steel, with a single crank, and the balance iron is connected to the crankshaft as a whole with special bolts.

3. The connecting rod is made of No. 45 steel, with a thin-walled sheet at the big end and a copper sleeve at the small end.

4. Cylinders: The first and second cylinders are made of HT250 steel, the third cylinder is made of 45 steel, and the fourth cylinder is made of 40Cr steel. Water chambers are arranged on all cylinders.

6. Pistons: The material of the first-stage piston is ZL104, the material of the second-stage piston is HT250, and the material of the third and fourth-stage pistons is 45 steel.

7. Seals: The primary, secondary, and tertiary packing and piston rings (support rings) are made of polytetrafluoroethylene (PTFE). The tertiary packing is made of PEEK, and the tertiary piston rings are made of alloy cast iron.

8. Air valves: The first and second stage air valves are mesh valves made of stainless steel, and the third and fourth stage air valves are ring valves made of stainless steel.

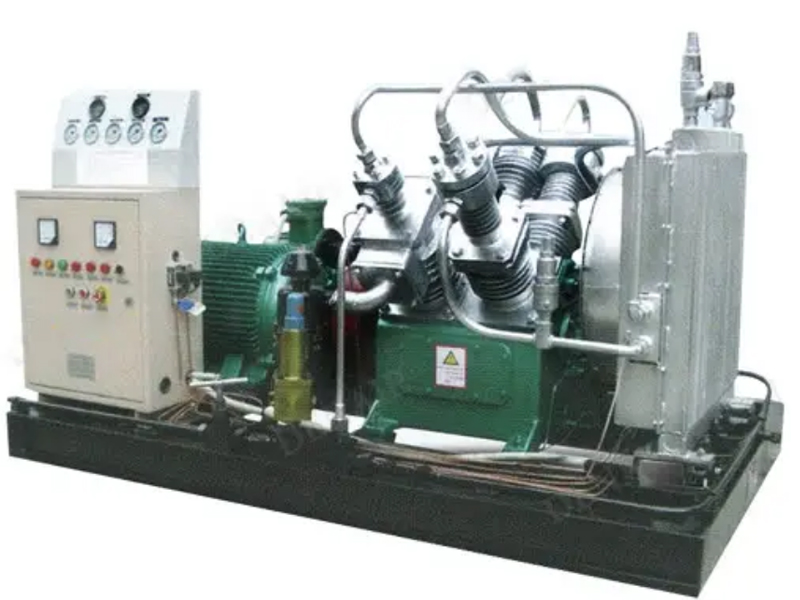

III. Instrument Control System

1. The instrument panel should be equipped with pressure gauges of level one, two, three, and four, compressor oil pressure gauge, and compressor water pressure gauge.

2. The compressor will automatically shut down when the discharge pressure is high, triggering an alarm.

3. The compressor will automatically alarm and shut down if the oil pressure is too low.

4. The compressor will automatically alarm and shut down if the water pressure is too low.

IV. Gas System

1. Safety valves are installed in each stage of the exhaust pipeline.

2. The compressor is equipped with a cooler.