-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

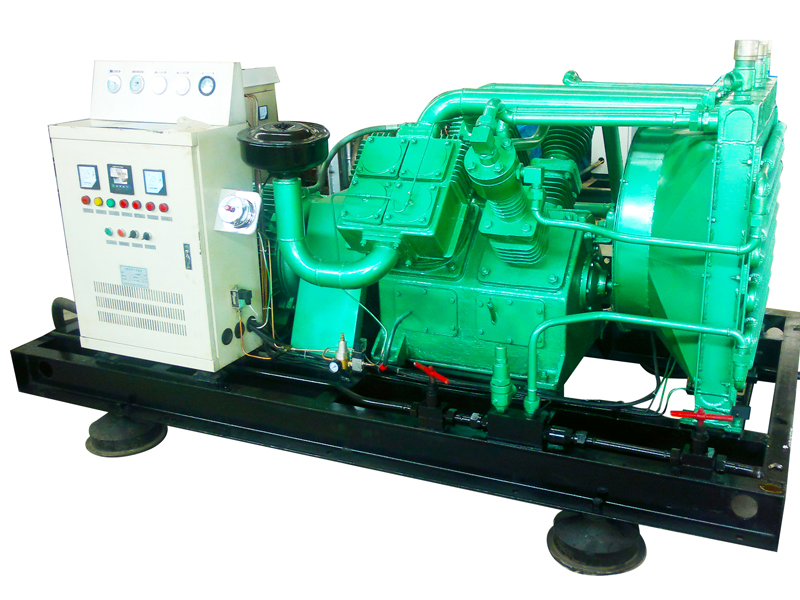

S-10/150 Skid-Mounted Air Compressor

I. Compressor Main Unit

Compressor main technical parameters

1. Compressor Model: S-10/150

2. Compressor type: S-type differential type

3. Compressor medium: Air

4. Rated exhaust volume: 10 m³/min

5. Rated pressure: Atmospheric pressure

6. Exhaust pressure: 15.0 MPa

7. Inlet air temperature: ≤40℃

8. Exhaust temperature: <200℃

9. Shaft power: 147.5kW

10. Compression levels: Four levels

11. Number of compressor rows: 8 rows

12. Cooling method: Air cooling

13. Lubrication method: Pressure lubrication

14. Transmission method: Reduction clutch

15. Lubricating oil consumption: 200-600g/h

16. Drive method: 160KW motor drive

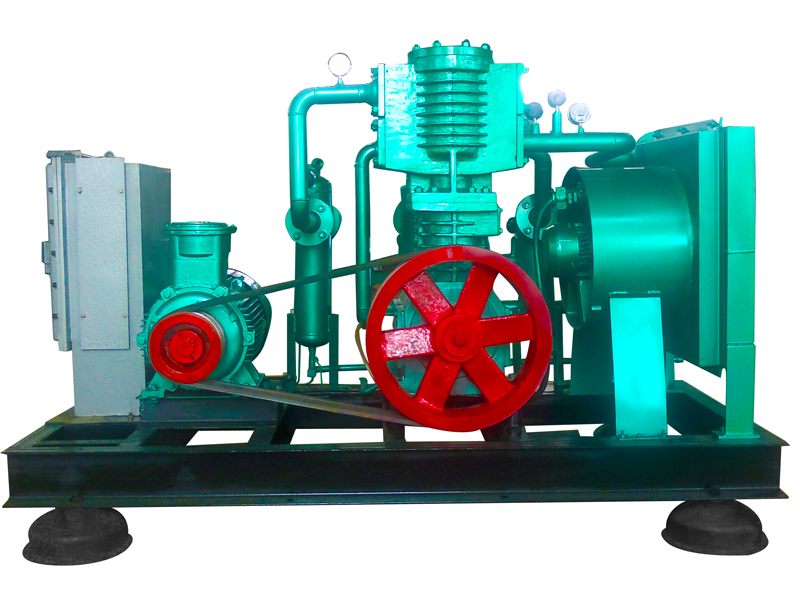

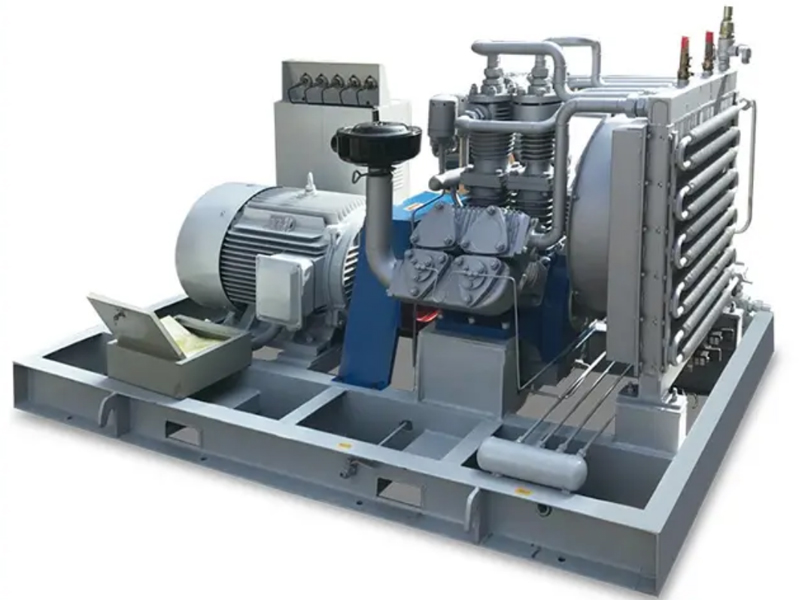

II. Main Structure of the Compressor

The compressor has a double-row sector structure, with two cylinders for each of the first, second, third, and fourth stages.

1. The crankcase is made of HT250 and is equipped with a breather to prevent the internal pressure from rising. The crankcase is also equipped with a lubricating oil level observation hole.

2. The crankshaft is made of 45 steel, with double cranks, and the balance iron is connected to the crankshaft as a whole with special bolts.

3. The connecting rod is made of 45 steel, with a thin-walled tile at the big end and a copper sleeve at the small end.

4. Cylinders: The first and second stage cylinders are made of HT250 steel, the third stage is made of QT600 steel, and the fourth stage is forged from 45 steel. Cooling fins are installed on all cylinders. The third and fourth stage guide cylinders are made of HT250 steel.

5. Cylinder Head: The first and second stage cylinder heads are made of HT250 steel, the third stage is made of QT600 steel, and the fourth stage is made of 45 steel. The first stage cylinder head has two intake valves and two exhaust valves; the second stage cylinder head has one intake valve and one exhaust valve; and the third and fourth stage cylinder heads have combination valves. Cooling fins are installed on each stage of the cylinder head.

6. Pistons: The first-stage piston is ZL104, the second-stage piston is HT200, the third-stage piston is HT250, the fourth-stage piston is 45 steel, and the guide piston is ZL104.

III. Instrument Control System

1. The instrument panel should be equipped with pressure gauges of level one, two, three, and four, compressor oil temperature gauge, and compressor oil pressure gauge.

2. The compressor will automatically shut down when the discharge pressure is high, triggering an alarm.

3. The compressor will automatically alarm and shut down if the oil pressure is too low.

IV. Gas System

1. Safety valves are installed in each stage of the exhaust pipeline.

2. The compressor is equipped with primary, secondary and tertiary coolers.

3. The compressor is equipped with primary and secondary oil-water separators.