-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

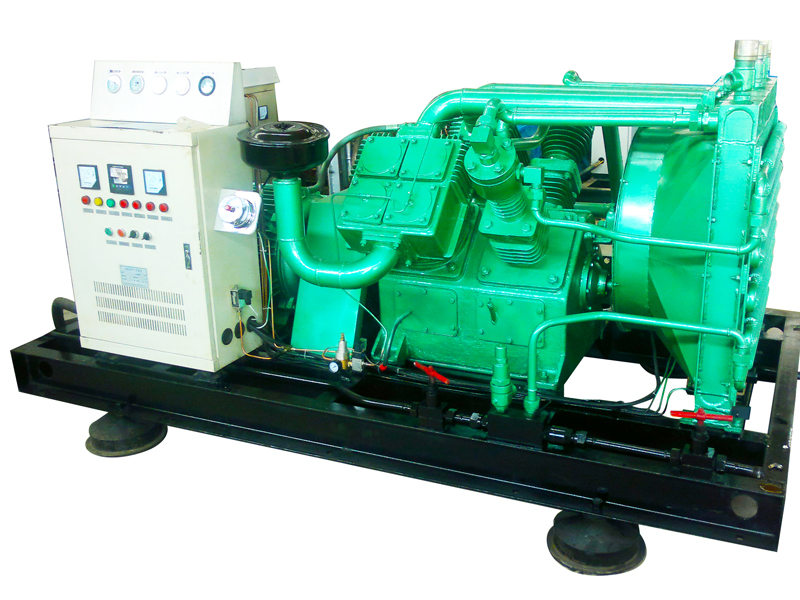

The entire unit is skid-mounted, with the compressor unit housed within a metal casing. The entire unit can be moved as a whole using a lifting device. The outer edge is a metal casing with multiple doors on the sides and rear, and ventilation openings on the top. The diesel engine's air intake and exhaust ports, and the compressor's air intake are located on the top of the casing. Lighting is installed inside the casing, and a lifting device is located on the top of the casing; the doors are locked. The front section is a large control room, decorated with elegant panels, and has a door leading to the unit; the instrument control cabinet is installed inside the control room. The overall dimensions of the casing are (length × width × height): 7500 × 2160 × 2300 (mm). The compressor is located on the side of the control room, and the diesel engine is at the rear. A check valve is installed at the final compressed air outlet to prevent backflow of high-pressure air after shutdown.

3. Overall machine parameters

3.1 Compressor Unit

3.1.1 Rated volumetric flow rate: 1.2 m³/min (inlet condition)

3.1.2 Standard volumetric flow rate: 30.3 Nm³/min

3.1.3 Intake pressure 2.40 MPa

3.1.4 Exhaust pressure 15.0 MPa

3.1.5 Control room dimensions (length × width × height): 1300 × 2160 × 2300 mm

3.1.6 Workshop (Length × Width × Height) 6200 × 2160 × 2300 mm

3.1.7 PLC programmable controller is used.

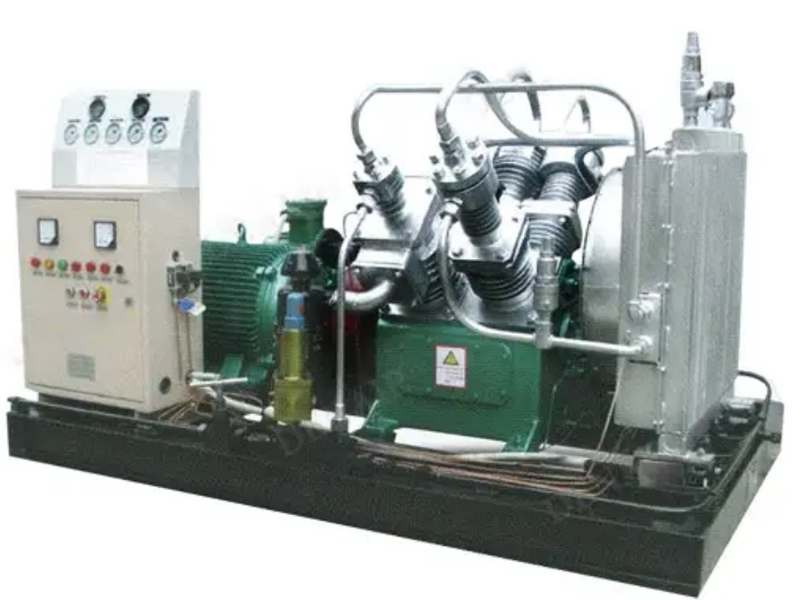

3.2 Compressor

3.2.1 Compressor model SF-1.2/24-150

3.2.2 Structural Form: Double S-type, air-cooled, oil-lubricated, 2-stage compression, single-acting.

3.2.3 Compressed Medium: Air

3.2.4 Nominal volumetric flow rate: 1.2 m³/min (inlet condition)

3.2.5 Inhalation pressure 2.4 MPa

3.2.6 Exhaust pressure 15.0 MPa

3.2.7 Intake temperature ≤95 ℃

3.2.8 Exhaust temperature ≤200 ℃

3.2.9 Compressor speed: 1330 r/min

3.2.10 Stroke 100 mm

3.2.11 Shaft power ≤195 kW

3.2.12 Lubricating oil consumption: 350g/h

3.2.13 Lubrication Methods: Crankshaft, connecting rod, piston pin: oil pump circulation lubrication; Cylinder, piston: splash lubrication.

3.2.14 Transmission Method: Hydraulic Clutch Reducer

3.2.15 Automatic Control: PLC Control

3.2.16 Total weight of the machine: Approximately 8000 kg

3.2.17 Air Inlet Type and Dimensions: A pre-installed welding flange is provided, fitted with a ø76×5 steel pipe (flange model: HG20592.WN65-6.0M).

3.2.18 Exhaust port type and size: A female connector for welding ø38×5 steel pipe is provided.

3.3 Diesel Engine

Engine model: NTA855-P450 (Chongqing Cummins)

Rated power/rated speed: 336KW (450HP)/1800r/min

Maximum torque/speed: 1627 Nm (1200 B.FT) / 1300 r/min

Type: Four-stroke, in-line water-cooled.

Intake method: Supercharging, intercooling

Number of cylinders: 6

Cylinder bore and stroke: 140/152mm

Engine steering (including auxiliary drive): Counterclockwise (viewed from the flywheel end)

Starting method: Electric start DC24V

Speed controller: Full-range speed regulation

Rated fuel consumption rate under rated operating conditions: 196±5%g/kW.h

Oil consumption rate: ≤0.12 g/kW.h

Engine idle speed: 575~650r/min

Diesel fuel used in the engine: Ordinary light diesel fuel

Engine oil used: 15W-40CD

Coolant additives: Refer to the coolant instruction manual.

Engine starting performance: The engine can start smoothly at room temperature (-5°C) without preheating the engine oil and coolant. Starting time ≤10 seconds. With coolant preheated (≥35°C), starting time ≤5 seconds.

Low temperature start: -20℃ (equipped with a 24V external fuel heater)

3.4 Hydraulic Clutch Reducer

3.4.1 Model LJ250F

3.4.2 Transmission capacity: 0.25kW/r/min

3.4.3 Transmission Form: Two-stage cylindrical helical gear transmission

3.4.4 Clutch Type: Hydraulic wet multi-plate friction clutch

3.4.5 Input Coupling: Geared Rubber Flexible Coupling

3.4.6 Mechanical efficiency ≥96%

3.4.7 Connection time ≤8 s

3.4.8 Working oil pressure: 1.2~1.6 MPa

4. Component Requirements

4.1 Main Structure of the Compressor

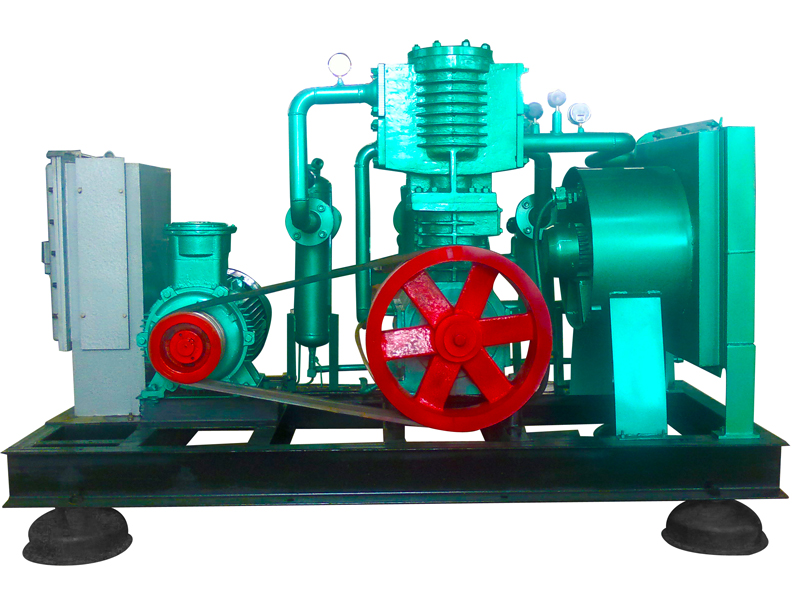

The compressor consists of a crankcase, crankshaft, connecting rod, piston, cylinder block, cylinder head, valves, etc., and is shaped like a double "S". This design is compact, small in size, and provides more balanced operation. The compressor's primary and secondary valves are Holbiger valves.

4.2 Cooling System

The diesel engine and compressor have independent cooling systems. The diesel engine uses a closed-loop water cooling system, while the compressor uses a fan-cooled system, and all coolers are air-cooled.

4.3 Automatic Control System

4.3.1 The automatic control system consists of an instrument panel, an automatic control system, and operating switches. The entire control system is installed in the operator's room in a cabinet-style configuration, with all instruments mounted on the cabinet. The operator's room is separated from the unit. The interior is decorated with decorative panels.

4.3.2 The instrument panel is equipped with various pressure gauges for the compressor; pressure gauges and temperature gauges for the compressor and diesel engine lubricating oil; diesel engine tachometer; clutch oil pressure gauge; start, stop, speed increase/decrease buttons and clutch disengagement/engagement buttons; various alarm lights, pressure controllers, lighting switches, and other components.

4.3.3 Equipment List

pressure gauge

(6 in total)Thermometer

(3 in total)Pressure controller

(4 in total)safety valve

(2 in total)TransmitterOther

First-stage intake pressureCompressor oil temperaturecompressor oil pressureOne exhaust safety valveDiesel engine oil temperatureDiesel engine tachometer

First stage exhaust pressureclutch oil temperaturecompressor ultra-high pressureSecondary exhaust safety valveDiesel engine water temperatureButton

Secondary exhaust pressureDiesel engine oil temperatureClutch oil pressureindicator lights

compressor oil pressureFirst-stage intake pressureManual drain valve

Diesel engine oil pressure1 vent valve

Clutch oil pressure1 air supply valve

1 check valve

Automatic drain valve

4.3.4 Automatic Control

The automatic control system consists of DC electrical components such as a programmable logic controller (PLC) and air switches. The operating switches consist of various stages of drain valves, a final vent valve, and an air supply valve.

The automatic control system is equipped with the following automatic protections, which are controlled by a programmable logic controller (PLC).

4.3.4.1 Starting Protection

The pressure of both the diesel engine lubricating oil and the compressor lubricating oil is driven by the diesel engine.

a. When the diesel engine starts for more than 20 seconds, the diesel engine oil pressure must be greater than 0.18 MPa. Otherwise, the low diesel engine oil pressure alarm indicator will light up, and the engine will automatically shut down after 12 seconds.

b. 60 seconds after the diesel engine starts, the compressor oil pressure must be >0.15MPa; otherwise, the low compressor oil pressure alarm indicator will light up and the engine will automatically shut down after 12 seconds.

c. After the diesel engine has been started for 60 seconds, the deceleration clutch oil pressure should be 0.5 MPa without protection. When the deceleration clutch "engage" button is pressed, if the start time is >20 seconds, the deceleration clutch oil pressure must be >1.0 MPa; otherwise, the low deceleration clutch oil pressure alarm indicator will illuminate, and the engine will automatically shut down.

4.3.4.2 Automatic Control Operation

a. When the compressor unit is operating normally, if any of the following conditions occur: diesel engine lubricating oil pressure < 0.18MPa, compressor lubricating oil pressure < 0.15MPa, or reduction clutch oil pressure < 1.0MPa, the diesel engine will automatically shut down. When the secondary exhaust pressure > 15.5MPa, the diesel engine will automatically shut down.

4.3.4.3 Monitoring of operating parameters

a. Diesel engine coolant temperature alarm

When the diesel engine outlet water temperature is greater than 95℃, the diesel engine outlet water temperature is high and the alarm indicator light will illuminate.

b. Diesel engine oil temperature

The diesel engine oil temperature is displayed on a temperature gauge ranging from 0 to 125°C, with the actual oil temperature being <120°C.