-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

I. Main Technical Parameters of the Compressor

1. Medium composition: air

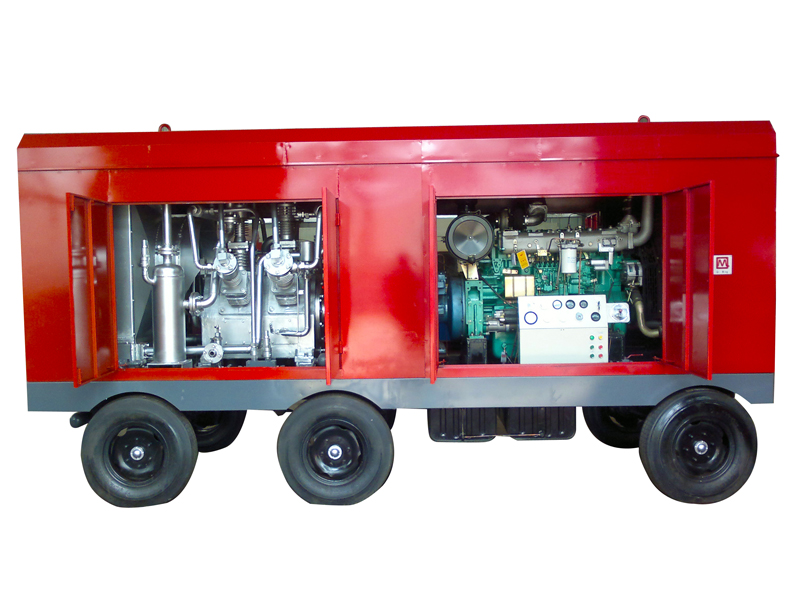

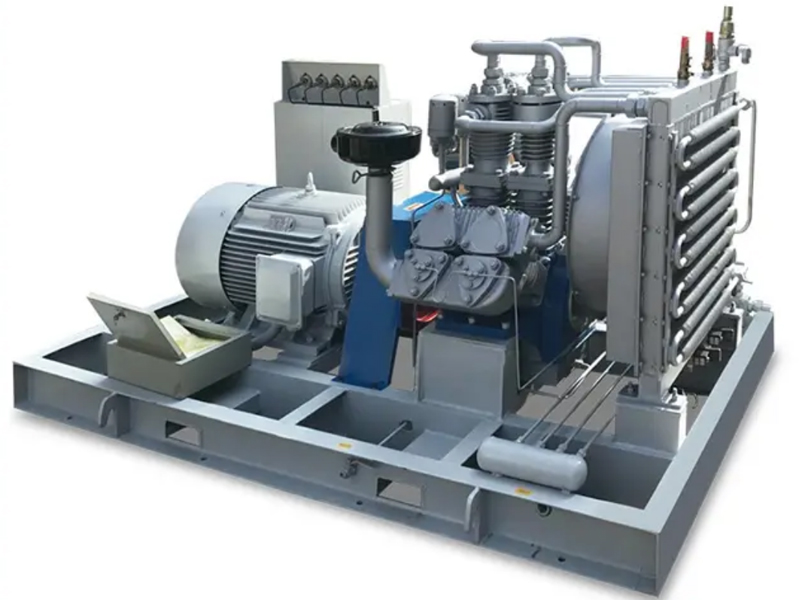

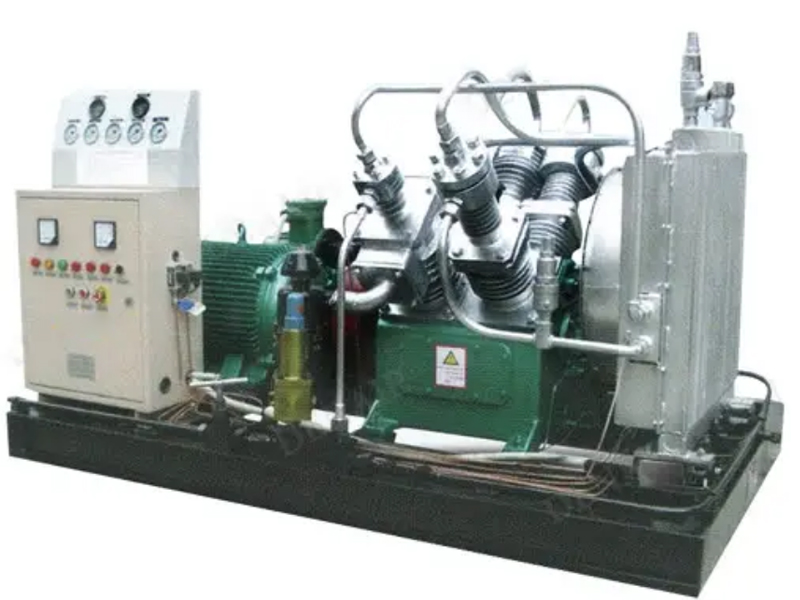

2. Compressor Model: SF-10/30DY Electric Stationary Air Compressor

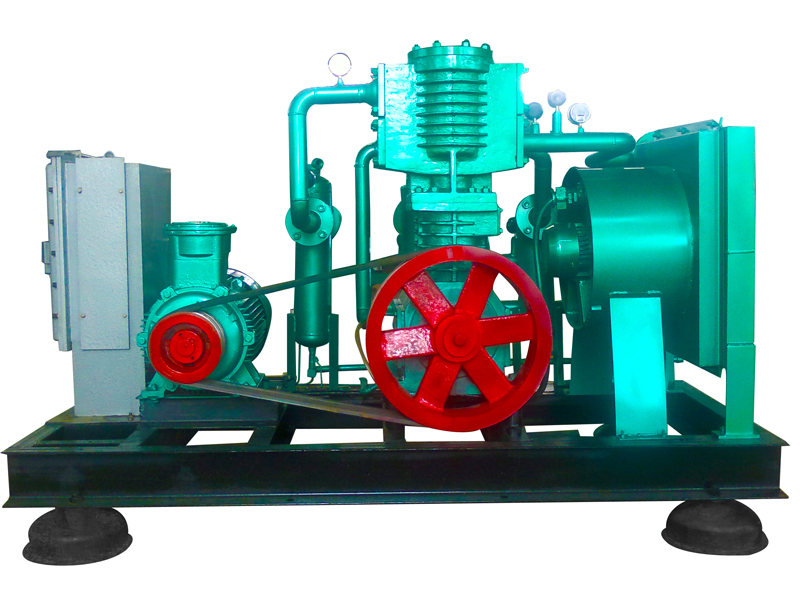

3. Structural form: S-shaped, air-cooled

4. Compression stages: Three-stage compression

5. Cylinder diameter for each grade (mm): Grade 1: 260*2, Grade 2: 160*2, Grade 3: 80*2

6. Nominal volumetric flow rate (m³/min): 10

7. Inhalation pressure: MPa(G): Atmospheric pressure

8. Exhaust pressure: MPa(G): 3.0

9. Inhalation temperature (°C): ≤40

10. Gas supply temperature (°C): ≤180

11. Compressor speed (r/min): 980

12. Transmission method: Direct coupling

13. Control method: Automatic unloading upon reaching pressure, overpressure alarm and shutdown, and electronic automatic sewage discharge.

14. Lubrication method: Combined lubrication of oil pump and splash.

15. Installation method: Electric mobile type (with cover)

16. Lubricating oil consumption: 125g/h

17. Noise dB(A): ≤90

18. Powertrain: Y355M-6 110KW/980rpm

19. Stroke: 120mm

20. External dimensions (length × width × height) mm: Approximately 4000 × 1800 × 1900

21. Weight (kg): Approximately 4000

22. Supply price: 10,000 RMB/unit

23. Delivery period: 35 days per unit.

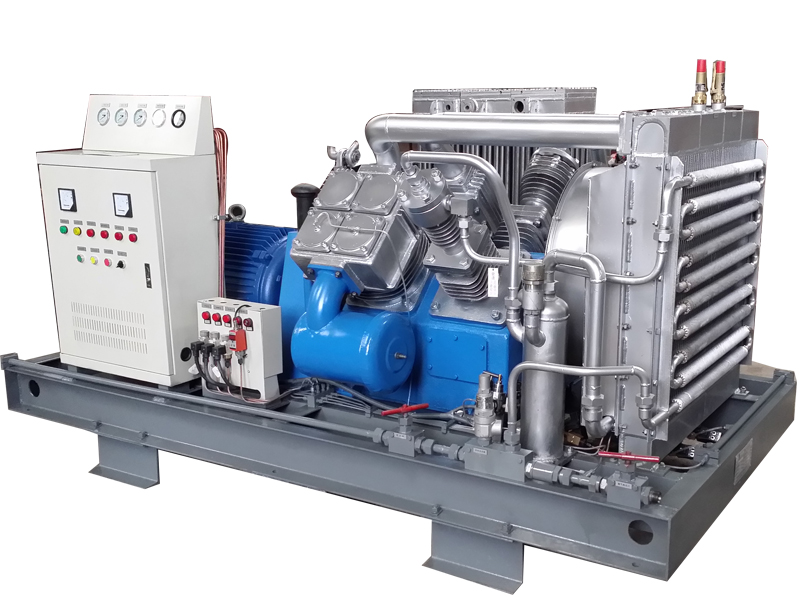

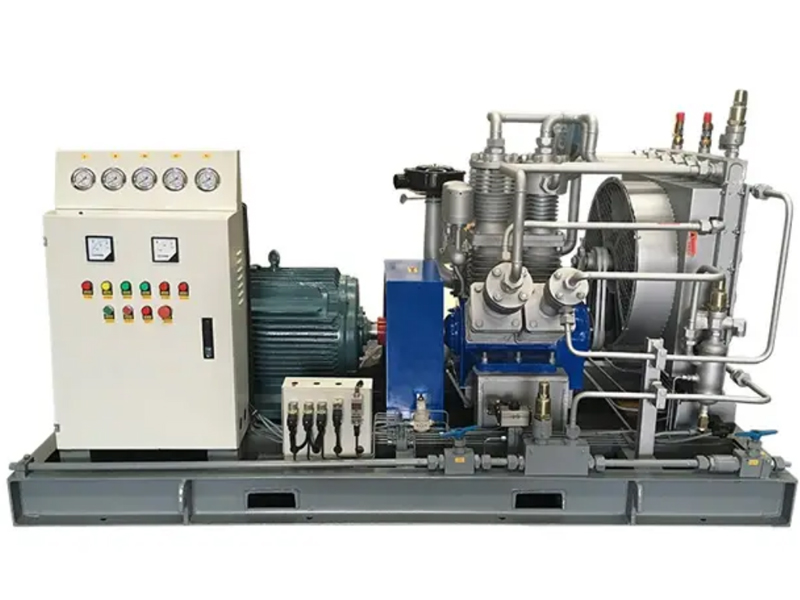

II. Compressor Main Unit

1. Crankcase components:

The crankcase has side covers and oil sight glasses on both sides for disassembly and inspection. The front section, which is the power connection end, is equipped with a bearing housing and a front bearing cover. The fan bracket on the upper part of the rear bearing cover supports the fan components. The upper part has a cylinder support plane, and the top surface is equipped with a breather. The bottom of the crankcase contains special compressor oil.

2. Crankshaft, connecting rod and components

The crankshaft has connecting rods mounted on its crankshaft, rolling bearings at both ends, a flywheel at the large end connected to a flexible coupling, and a pulley near the bearing at the small end to drive the cooling fan. The crankshaft is lubricated by the connecting rod's oil pump and by oil splashes onto the crankshaft and piston pins.

3. Piston assembly:

The piston assembly consists of three stages and eight cylinders. The pistons are made of castings and aluminum alloys, and each piston is equipped with piston rings.

4. Cylinder components:

The cylinder components are equipped with heat sinks to increase the heat dissipation area. The cylinder head contains intake and exhaust valve components, intake and exhaust pressure cylinders, and intake and exhaust pressure caps.

5. Intake and exhaust valve components:

The intake and exhaust valves are steel ring valves and combination valves.

6. Cooler and fan components:

The system consists of two parts: an aftercooler and a cooling fan. It is mounted on a base by uprights. The upper part of the aftercooler is equipped with a safety valve, and the lower part is equipped with a drain valve. A guide cover and a protective cover are installed facing the crankcase. A suction-type cooling fan is installed in the middle. A fan bracket mounts the fan assembly on the crankcase. The fan is driven to rotate by the crankshaft pulley at the end of the crankcase via a V-belt.

III. Compressor Control System

1. The instrument panel is equipped with a three-stage pressure gauge, a compressor oil temperature gauge, and an oil pressure gauge.

2. The compressor automatically unloads when pressure is reached.

3. The compressor will automatically shut down if it is overpressured.

4. The exhaust pressure can be adjusted within the rated pressure range according to user needs.