-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

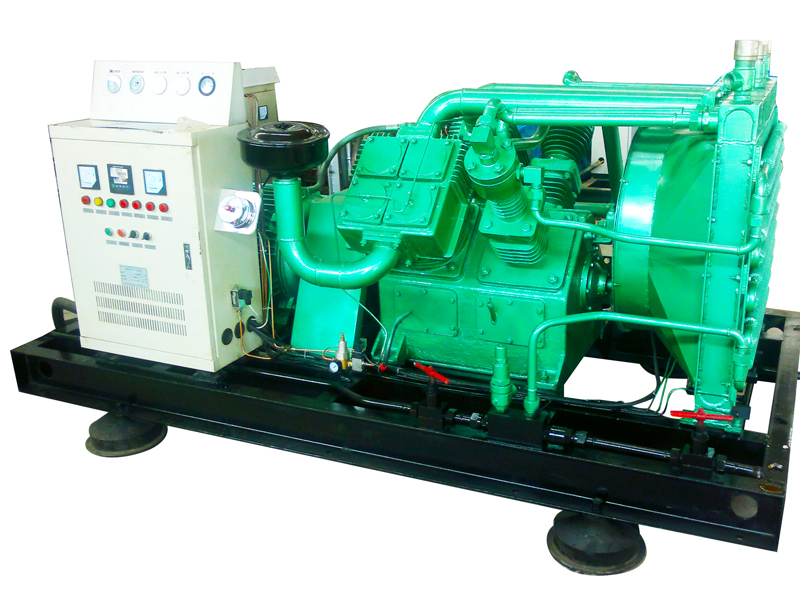

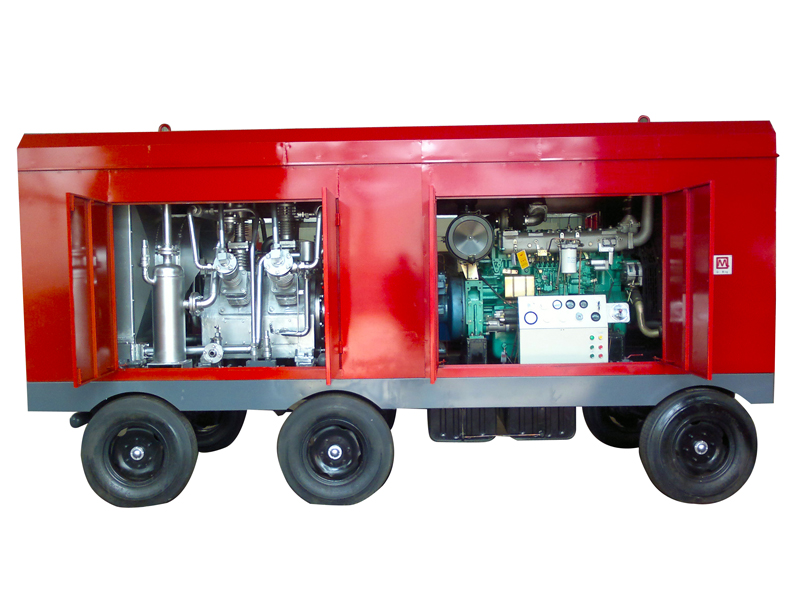

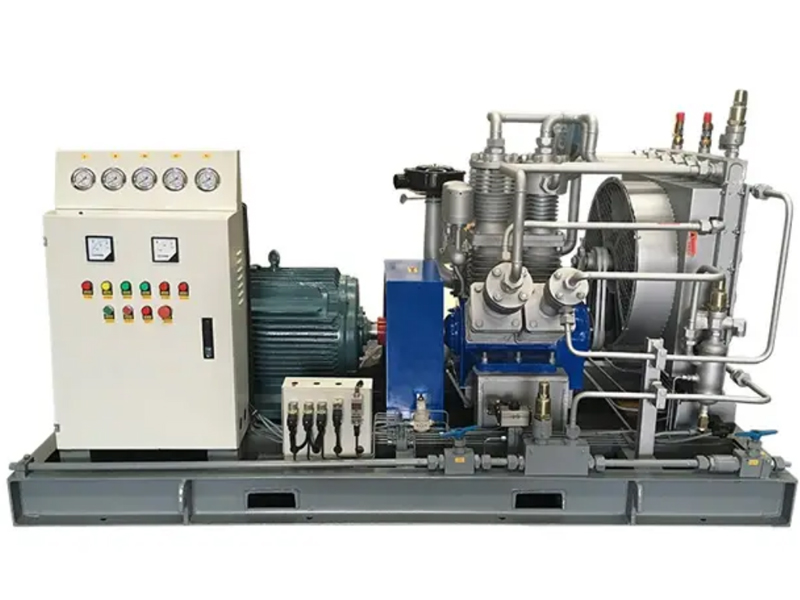

8 cubic meter 85 kg pressure electric stationary air compressor

I. Main Technical Parameters of the Compressor

1. Compressor Model: SF-8/85DG

2. Compressor type: S-type air-cooled piston type

3. Compressor medium: Air

4. Rated exhaust volume: 8 m³/min

5. Rated pressure: Atmospheric pressure

6. Exhaust pressure: 8.5 MPa (Maximum exhaust pressure: 10.0 MPa)

7. Inlet air temperature: ≤40℃

8. Exhaust temperature: <180℃

9. Shaft power: 106.8kW

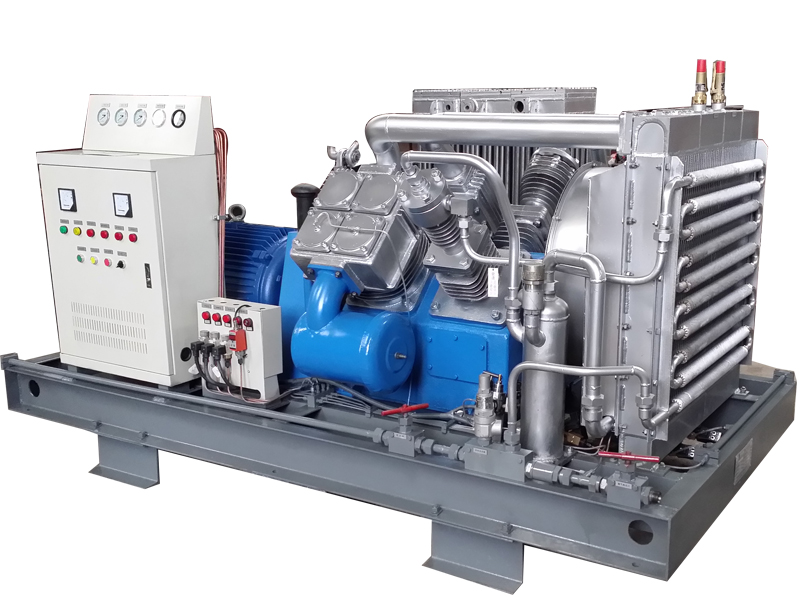

10. Compression levels: Four levels

11. Number of compressor rows: 8 rows

12. Cooling method: Air cooling

13. Lubrication method: Splash lubrication

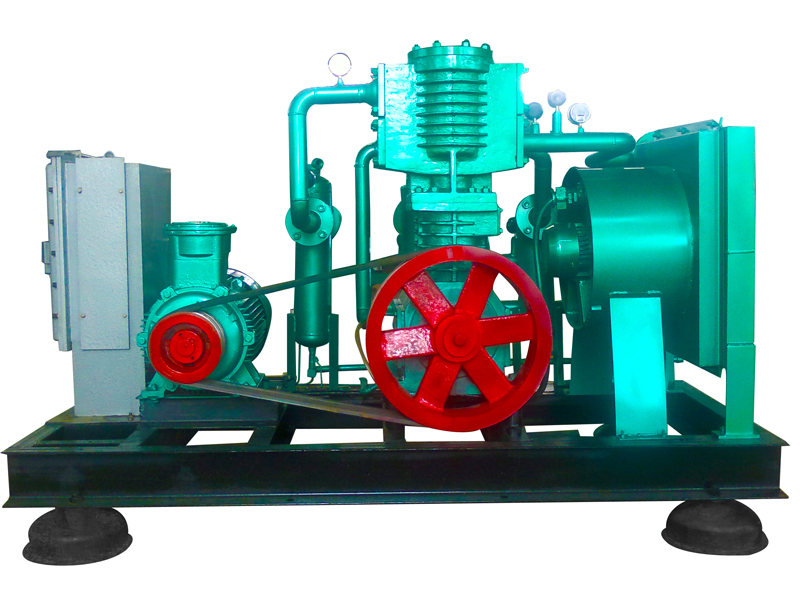

14. Transmission method: Direct connection via coupling

15. Lubricating oil consumption: 200-600g/h

16. Drive method: 132KW motor from Jiangsu Xindali Motor Co., Ltd., speed 980r/min, protection level: IP54, duty cycle: S1

17. External dimensions: Electric fixed type 3500×1500×1500 (mm)

18. Total weight: Electric stationary type: approximately 4.0 tons.

II. Main Structure of the Compressor

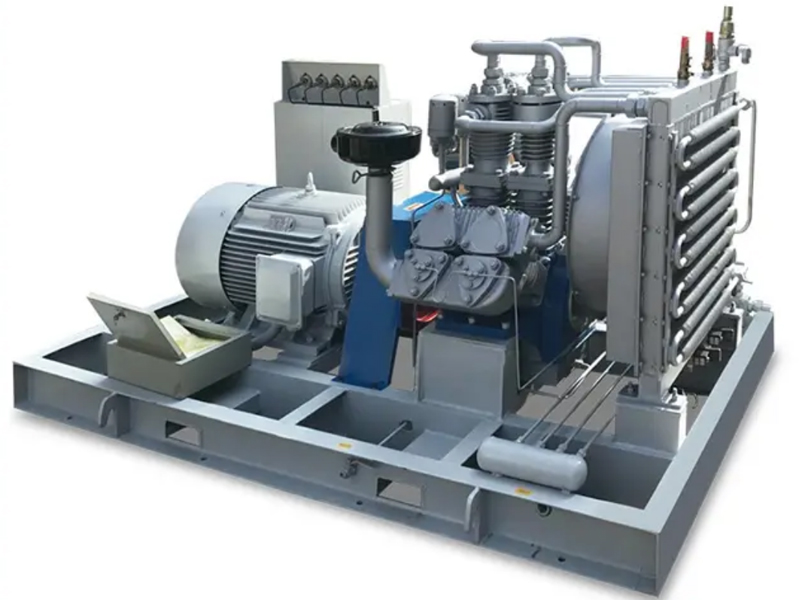

The compressor has a double-row S-shaped structure with two cylinders for each of the first, second, third, and fourth stages.

1. The crankcase is made of HT250 and is equipped with a breather to prevent the internal pressure from rising. The crankcase is also equipped with a lubricating oil level observation hole.

2. The crankshaft is QT600, with double cranks. The balance iron is cast as one piece with the crankshaft.

3. The connecting rod is QT600, with a thin-walled tile at the big end and a copper bushing at the small end.

4. Cylinders: The first and second stage cylinders are made of HT250 steel, the third stage is made of QT600 steel, and the fourth stage is forged from 45 steel. Cooling fins are installed on all cylinders. The third and fourth stage guide cylinders are made of HT250 steel.

5. Cylinder Head: The first and second stage cylinder heads are made of HT250 steel, while the third and fourth stage cylinder heads are made of 45# steel. The first and second stage cylinder heads are equipped with mesh intake and exhaust valves; the third and fourth stage cylinder heads are equipped with combination valves. Cooling fins are installed on each stage of the cylinder head.

6. Pistons: The first-stage piston is ZL104, the second-stage piston is HT200, the third and fourth-stage pistons are HT250, and the guide piston is ZL104.

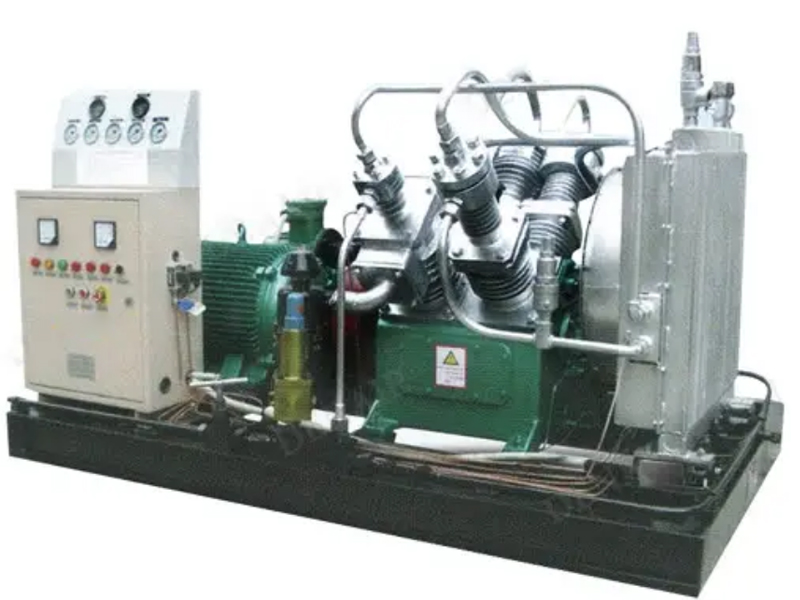

III. Instrument Control System

1. The instrument panel should be equipped with pressure gauges of levels one, two, three, and four (connected to the air tank pressure display). Also include a compressor oil temperature gauge and manual drain valves for each level.

2. The compressor automatically alarms and shuts down when the discharge pressure is high. The pressure adjustment range can be set; it will stop when the pressure reaches the set point and automatically restart when the pressure drops to the lower limit (this setting depends on your gas usage. A relatively slow pressure drop is required; otherwise, the high motor power and frequent starts can easily damage the motor).

IV. Gas System

1. Safety valves are installed in each stage of the exhaust pipeline.

2. The compressor is equipped with primary, secondary and tertiary coolers.

3. The compressor is equipped with a first, second, and third stage electromagnetic oil-water separation device, which can automatically discharge sewage at set times.