-

联系我们

|

-

微信

微信号:tel-15397675238扫一扫 联系我们

|

ENGLISH |

ENGLISH |

Русский язык

Русский язык

微信号:tel-15397675238扫一扫 联系我们

ENGLISH

ENGLISH Русский язык

Русский язык

![[list:title]](/static/upload/image/20241125/1732522854370300.jpg)

![[list:title]](/static/upload/image/20241125/1732522854175844.jpg)

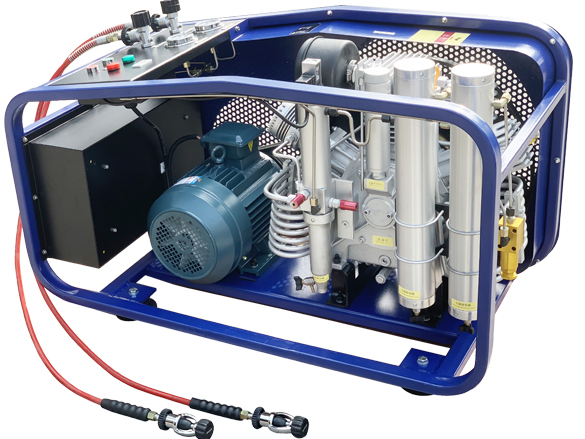

Product Description:

The HC-W400/ET is a professional-grade high-pressure air compressor, optimized and mass-produced based on a mature German model. This product employs three-cylinder, three-stage compression technology, equipped with a splash lubricati···

Product Description:

The HC-W400/ET is a professional-grade high-pressure air compressor, optimized and mass-produced based on a mature German model. This product employs three-cylinder, three-stage compression technology, equipped with a splash lubrication system, a final-stage safety valve, and a high-efficiency filtration device, ensuring long-term stable operation and high-purity air output. Core components undergo special processing: the final-stage piston is manufactured using a proprietary process, piston rings utilize Riken technology from Japan, and all castings are produced by large, specialized outsourced factories, ensuring robust and reliable quality.

The product is designed, manufactured, and inspected in strict accordance with the GB/T 3853-2017 standard for positive displacement compressors. The compressed air quality also meets the requirements of GB/T 31975-2015 "Technical Requirements for Compressed Air for Respiratory Protection" and GB 18435-2007 "Diving Breathing Gases and Testing Methods." Its high-efficiency filtration system effectively removes oil and impurities, filtering fine particulate matter (PM2.5) in inhaled air to a safe level below 10 micrograms, complying with relevant World Health Organization (WHO) standards. The output gas is clean and odorless, suitable for industrial scenarios requiring high-pressure, pure air sources, and provides safe and reliable breathing air for humans.

This model has been on the market for over ten years, has been proven in the market, and has received widespread praise from users. It is a trusted high-pressure air source solution for various industries.

Product Parameters

| project | parameter |

|---|---|

| model | HC-W400/ET |

| Displacement | 400 L/min |

| Exhaust pressure | 225 / 330 bar |

| Compression levels | Level 3 |

| driving method | Electric three-phase 380V / 50Hz |

| Rated speed | 1650 rpm |

| power | 7.5 kW |

| horsepower | 7.5 hp |

| weight | 235 kg |

| Dimensions (length × width × height) | 117 cm × 61 cm × 71 cm |

| Gas supply interface | G5/8 × 2 |

| Control method | Automatic shutdown |

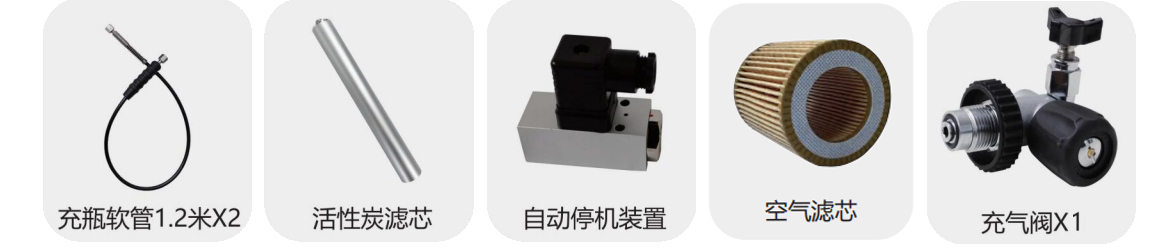

Standard configuration (included with the machine)

Features

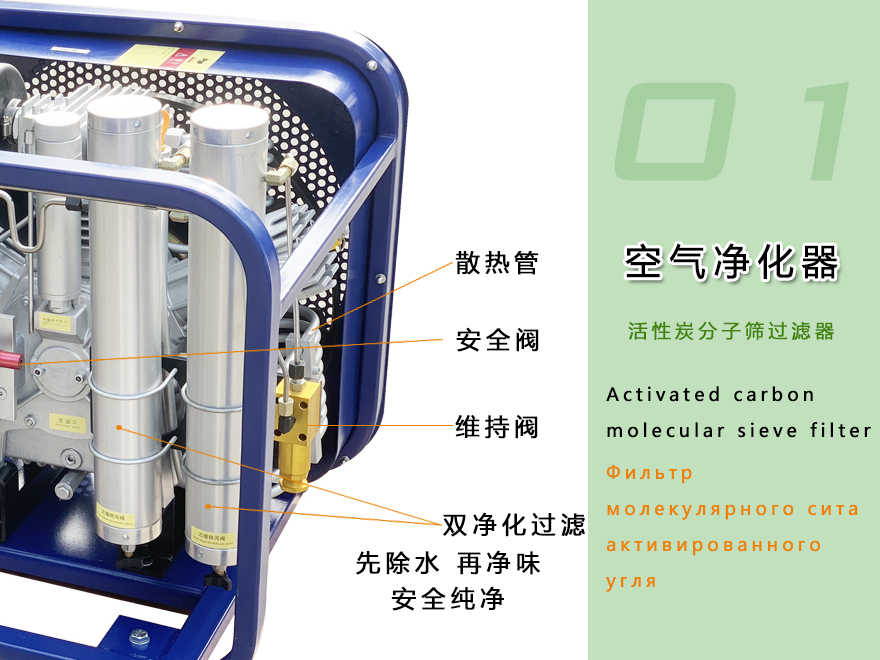

I. Core Compression and Purification System

High-efficiency compression design: It adopts a three-cylinder three-stage compression, equipped with a splash-type high-efficiency lubrication and stainless steel cooling system to ensure a long-lasting and stable high-pressure air supply.

Multiple purification safeguards: Built-in dual purification system (activated carbon, molecular sieve, carbon monoxide absorber), combined with pre-air filter and process oil-water separator, ensures that the output air quality meets diving and fire-fighting breathing standards.

Flexible pressure options: Standard inflation pressure is 225 Bar or 330 Bar to meet the needs of different gas cylinders.

II. Safety Protection Design

Comprehensive mechanical protection: Each compression stage is equipped with a safety valve for automatic overpressure relief; rotating parts are fitted with protective covers to ensure operational safety.

Intelligent electrical protection: The motor has multiple protection functions including overload, overheat, and undervoltage protection.

Visualized operating status: Equipped with a shockproof pressure gauge (0-5800psi/400bar) and an operating timer for easy monitoring.

III. Durable Structure and Heat Dissipation

Rugged chassis: The precision-manufactured compressor base is durable.

High-efficiency heat dissipation: It adopts a high-strength nylon cooling fan, which has excellent heat dissipation effect.

IV. Ease of Use and Configuration

Dual-outlet high-efficiency filling: It has two output ports and can fill two gas cylinders at the same time.

Flexible drive method: Supports electric motor drive or gasoline engine drive, adapting to diverse field power supply conditions.

Easy maintenance: The filter media in the purification system is reusable and easy to replace, reducing costs.

V. Value-added services and customization

Authoritative certification support: We can provide third-party testing reports and documents required for bidding and tendering.

Highly customizable: Supports OEM/ODM, can be customized for different national voltage frequencies, and can be equipped with a PLC intelligent control system.

Application areas

Firefighting Breathing Application: This system is deployed in air supply stations of various fire brigades and on various fire trucks, and is specifically designed for fire scenes and rescue and disaster relief environments. Under dangerous conditions such as dense smoke, toxic gases, steam, or lack of oxygen, it can provide firefighters with highly purified, clean, odorless, safe, and reliable compressed air, ensuring their breathing safety and thus supporting the efficient and safe conduct of firefighting, rescue, disaster relief, and medical care.

Diving breathing applications: Suitable for diving clubs, diving enthusiasts, marine aquaculture, rescue operations, marine equipment, well operations, fishing, aquaculture, sunken object salvage, underwater engineering, water parks, shipbuilding, and other fields. The system provides divers with clean, safe, and breathing-compliant high-pressure air, which is filled into cylinders for use underwater and in other environments where normal air cannot be directly breathed.

Applications of airtightness testing: Primarily used for airtightness inspection and pressure resistance testing of various pressure vessels, high-pressure gas cylinders, valves, pipelines, and other equipment. It covers strength testing of materials such as high-precision stainless steel welded pipes, titanium alloy welded pipes, high-pressure vessels, automotive parts, and pressure components. It also supports pressure resistance and burst strength testing and non-destructive testing of precision instruments, special equipment, aviation hoses, and oil tools. Furthermore, it can perform calibration and pressure resistance testing of safety valves, comprehensively identifying potential safety hazards in equipment and materials to ensure operational safety.