-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

![[list:title]](https://www.hc986.com/static/upload/image/20250106/1736125134141017.jpg)

The HC-X810Z is a professional-grade high-pressure compressor designed specifically for breathing air supply and high-precision airtightness testing applications. This unit utilizes four-cylinder, four-stage compression technology, offering a displacement of up ···

The HC-X810Z is a professional-grade high-pressure compressor designed specifically for breathing air supply and high-precision airtightness testing applications. This unit utilizes four-cylinder, four-stage compression technology, offering a displacement of up to 810 L/min and a maximum charging pressure option of 420 bar. Equipped with an advanced PLC touchscreen control system, multiple safety protection mechanisms, and a highly efficient triple purification system, it ensures clean, safe, and reliable output air. Whether used for firefighting, diving operations, or industrial testing, the HC-X810Z provides stable and efficient power support.

| project | Specifications (original units) | Specifications (converted to SI units/supplementary information) |

|---|---|---|

| model | HC-X810Z | - |

| Displacement | 810 L/min | 810 liters/minute |

| Exhaust pressure | 225 bar / 330 bar / 420 bar (optional) | 22.5 MPa / 33.0 MPa / 42.0 MPa (or approximately 3265 / 4785 / 6090 psi) |

| Compression levels | Level 4 | - |

| driving method | Electric, three-phase 380V / 50Hz (voltage/frequency can be customized) | - |

| Rated speed | 1350 rpm | 1350 rpm |

| Rated power | 18.5 kW | 18.5 kilowatts |

| horsepower | 20 HP | 20 horsepower (metric horsepower) |

| Lubrication method | Forced oil pump lubrication | - |

| Transmission method | Belt drive | - |

| weight | 585 kg | 585 kg (≈ 1290 lbs) |

| External dimensions | 148 cm × 110 cm × 160 cm | 1.48 m × 1.10 m × 1.60 m (Length × Width × Height) |

| Gas supply interface | G5/8 × 4 (can fill 4 gas cylinders simultaneously) | - |

| Control method | PLC intelligent touch screen | Programmable Logic Controller and Touch Screen Integrated Control System |

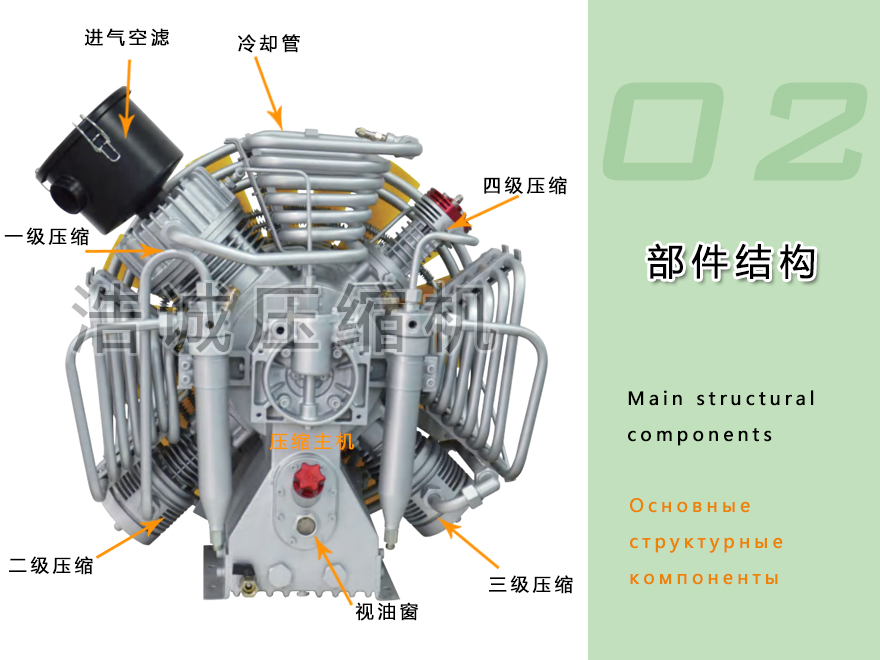

Core features and advantages

1. Excellent air quality

The quality of the gas produced strictly complies with international standards for diving breathing air (such as EN12021) and fire-fighting breathing air.

Equipped with a three-stage breathing air purification system (activated carbon, molecular sieve, and carbon monoxide absorbent) to ensure clean, safe, and odorless air.

It features a built-in oil-water separator and automatic drain function, effectively removing condensate and impurities during the compression process.

2. Reliable and durable design

The robust four-cylinder, four-stage compression unit ensures smooth operation and a long service life.

The compressor base is well-made and durable.

It adopts a stainless steel cooling system, which has high heat dissipation efficiency and corrosion resistance.

High-strength nylon cooling fan, low noise, and better heat dissipation.

3. Comprehensive security protection

Each compression stage is equipped with a safety valve for automatic overpressure relief.

The motor is equipped with overload, overheat, undervoltage, and phase sequence protection.

It integrates oil shortage protection, low temperature protection, and emergency stop functions.

All rotating parts are equipped with protective covers to ensure operator safety.

Shockproof pressure gauge (0-7251 PSI / 500 bar), with clear and reliable readings.

4. Intelligent and convenient control

The PLC intelligent touch screen control system is intuitive and easy to operate.

It supports both Chinese and English control panels, catering to users worldwide.

It has automated functions such as automatic shutdown, automatic sewage discharge, and temperature control system.

The air intake is equipped with a paper filter air filter to protect the compressor and extend the life of components.

The end pressure maintaining valve design can extend the service life of the purification filter element.

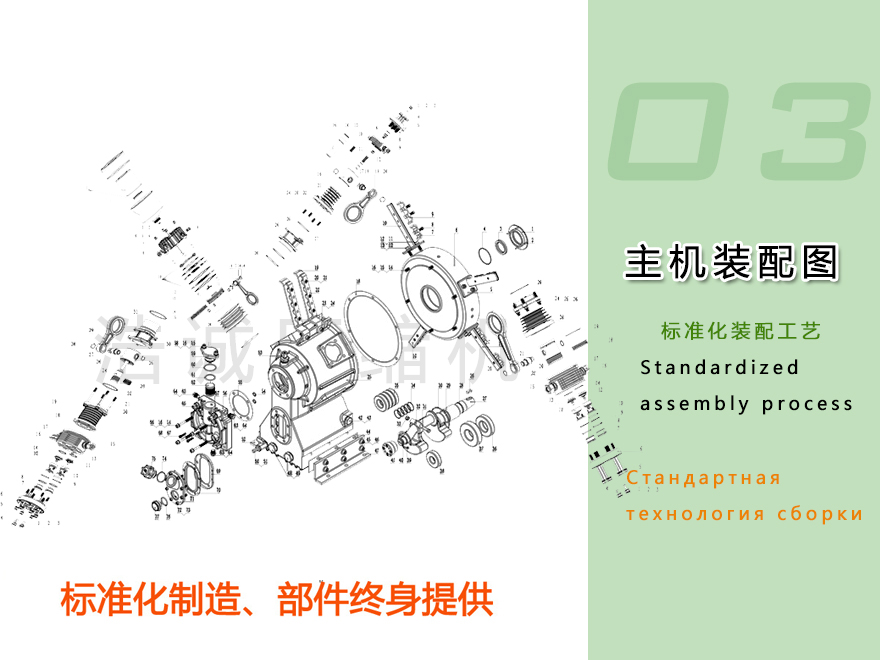

5. Economical maintenance costs

The packing cylinder of the purification system is reusable, easy to replace, and saves on long-term consumable costs.

The forced oil pump lubrication system ensures optimal lubrication for all moving parts, reducing wear.

Firefighting breathing air supply: Suitable for fire stations and fire trucks, providing firefighters with safe and clean breathing air at fire and rescue sites.

Diving and Underwater Operations: Providing reliable high-pressure breathing air for industries such as diving clubs, maritime rescue, underwater engineering, and aquaculture.

Industrial air tightness testing: Used for pressure testing and air tightness inspection of equipment such as pressure vessels, valves, pipelines, automotive parts, and aviation hoses to ensure industrial safety and quality.

We are seeking partners worldwide, including distributors, wholesalers, and industry integrators, to jointly expand our market.

Cooperation and support:

OEM/Private Label Services: We can customize product appearance and packaging according to your brand requirements.

Customized solutions: Supports different national voltages, frequencies, and special function configurations.

Optional upgrades: Offers value-added features such as automatic shutdown control and intelligent monitoring.

Comprehensive technical support: A professional team provides pre-sales consultation and after-sales support.

Why choose us?

Reliable quality: Strict quality control ensures the equipment is highly durable.

Competitive advantages: Factory direct supply, high cost performance, and considerable profit margin.

Full support: From sample testing to bulk orders, we provide you with a one-stop service.

Contact us for more information, sample testing, or bulk quotes! Let's work together to provide safe and clean high-pressure air solutions for the global market.