-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

![[list:title]](https://www.hc986.com/static/upload/image/20250117/1737113629226141.jpg)

HC-W400ZT High-Pressure Breathing Air Compressor - Professional-Grade High-Pressure Pure Air Solution

The HC-W400ZT is a high-performance, high-pressure breathing air compressor based on an optimized design of an advanced German m···

HC-W400ZT High-Pressure Breathing Air Compressor - Professional-Grade High-Pressure Pure Air Solution

The HC-W400ZT is a high-performance, high-pressure breathing air compressor based on an optimized design of an advanced German model and mass-produced. Its final-stage piston is manufactured using a special process, and the piston rings utilize Riken technology from Japan. All castings are produced by a professional, large-scale foundry, ensuring superior durability and reliability. This product has been on the market for over ten years, winning widespread recognition from users worldwide for its stable performance and excellent air quality.

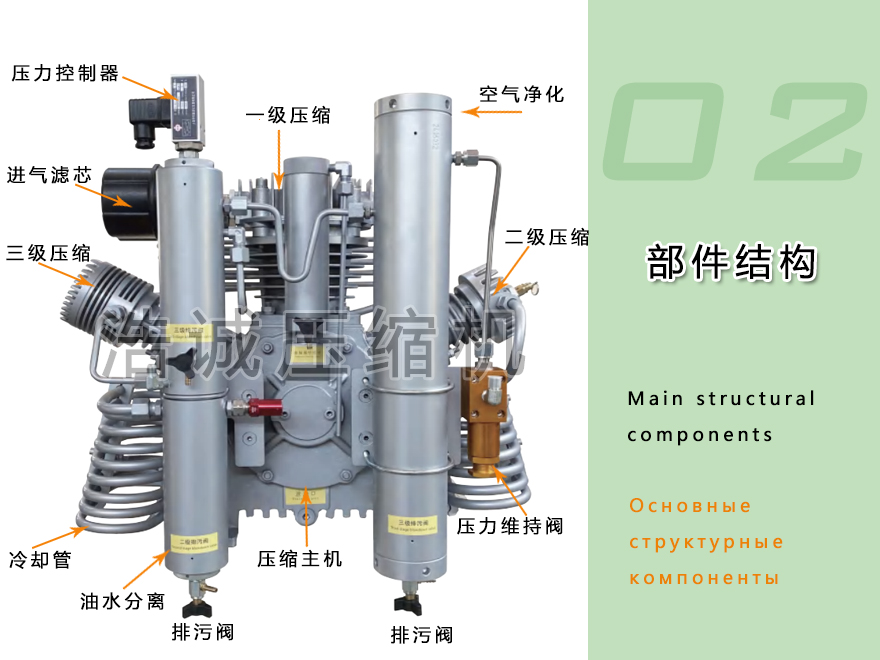

This machine adopts a three-cylinder, three-stage compression design, and is equipped with a splash lubrication system, a final-stage safety valve, and a high-efficiency filtration system. It can provide safe and reliable compressed air for various industries that require high-pressure, pure air sources, and is especially suitable for scenarios with strict requirements on the quality of air for human respiration.

The product is designed, manufactured, and inspected in strict accordance with the GB/T 3853-2017 standard "Positive Displacement Compressors". The quality of its output air meets the requirements of GB/T 31975-2015 "Technical Requirements for Compressed Air for Respiratory Protection" and GB 18435-2007 "Diving Breathing Gases and Detection Methods".

The HC-W400ZT can compress free air (1 bar / 0.1 MPa) in stages to a maximum working pressure of 330 bar (30 MPa). During compression, the air flows through a high-efficiency oil-gas separator and a multi-stage filtration system, thoroughly removing oil, impurities, and odors. It can also filter fine particulate matter (such as PM2.5) in the inhaled air to a safe level below 10 µg/m³, meeting the relevant standards of the World Health Organization (WHO). The output gas is pure, safe, and odorless, providing users with high-quality breathing air protection.

| Parameters | Specification | Explanation/Internationally accepted conversion |

|---|---|---|

| model | HC-W400ZT | High-pressure breathing air compressor |

| Displacement | 400 L/min | Approximately 14.1 CFM (cubic feet per minute) |

| Exhaust pressure | 225 / 330 bar | 3,263 / 4,786 psi (pounds per square inch) |

| Compression levels | Level 3 | Three-stage compression for higher efficiency and lower temperature rise. |

| driving method | Electric, three-phase 380V / 50Hz | Customizable to global voltage and frequency standards such as 440V/60Hz and 220V/60Hz. |

| Rated speed | 1650 rpm | revolutions per minute |

| Lubrication method | Splash | Simple, reliable, and easy to maintain |

| Transmission method | Belt drive | Smooth operation, low noise, and overload protection. |

| Cooling method | air-cooled | No external water circulation required, flexible installation |

| power | 7.5 kW | Approximately 10 HP (horsepower) |

| weight | 600 kg | Approximately 1,323 lbs (pounds) |

| Dimensions (L×W×H) | 170 × 100 × 175 cm | Approximately 67" × 39" × 69" (inches) |

| Gas supply interface | G5/8 * 2 | Two internationally compatible interfaces allow for simultaneous bottle filling. |

| Gas storage volume | 13.6 L | Built-in gas buffer tank for stable output pressure |

| Model Design | Box-type air-filled explosion-proof integrated machine | Integrated explosion-proof air box, safe and aesthetically pleasing. |

| Bottle quantity | 2 bottles | It can fill two gas cylinders at the same time. |

| Applicable gas cylinders | 6 ~ 12 L | Compatible with common diving bottle and breathing air cylinder volumes |

| Control method | PLC microcomputer control | Intelligent control, easy to operate, and comprehensive functions |

| Explosion-proof box working pressure | 40 MPa | 5,800 psi, high-strength safety design |

| Pressure regulation | Device with pressure reducing valve | The output pressure can be adjusted as needed. |

Standard configuration (included with the machine)

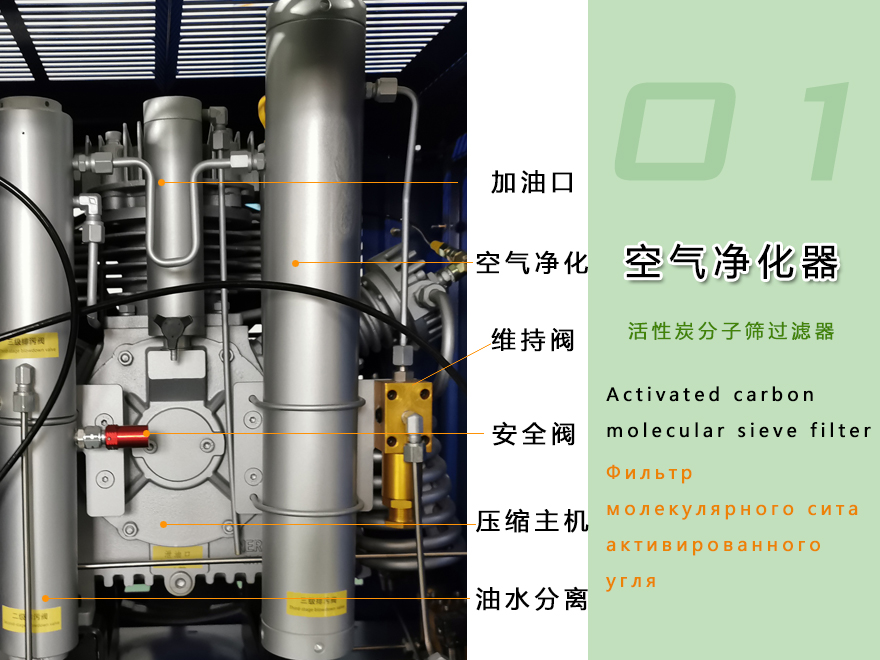

Exceptional air quality: Equipped with a triple purification system (activated carbon, molecular sieve, and carbon monoxide absorption layer), the output air meets international breathing air standards and satisfies high-requirement applications such as diving and fire fighting.

Reliable safety design: Each compression stage is equipped with a safety valve; the PLC control system integrates multiple protections such as overpressure, overheating, oil shortage, and motor overload; explosion-proof inflation chamber and protective covers for rotating parts ensure safe operation.

Highly efficient purification and filtration: Multi-stage oil-water separator (standard manual drain) and end-of-line precision filter effectively remove oil, water and particulate matter, with long filter life and low maintenance costs.

Intelligent and convenient operation: PLC touch screen control with functions such as running timer, automatic stop, and emergency stop. Optional automatic sewage discharge and temperature sequence protection are also available.

Strong adaptability: air-cooled design for easy deployment; customizable global voltage/frequency; offers 225 bar or 330 bar inflation pressure options.

Robust and Durable Structure: Optimized compressor body design, stainless steel cooling pipes, and high-strength nylon cooling fan ensure long-term stable operation.

| Design and Performance | - Three-cylinder, three-stage compressor for smooth and efficient operation.

- Splash lubrication for simple maintenance.

- High-strength nylon fan for excellent heat dissipation.

| Safety and Protection | - Inflatable explosion-proof integrated box design, operating pressure up to 40MPa.

- Safety valve for each stage, automatic overpressure release.

- Motor overload, overheat, and undervoltage protection.

- Full protective cover for rotating parts.

| Purification System | - Inlet paper filter for dust filtration.

- Multi-stage oil-water separator with manual drain.

- Three-stage end-of-line breathing air purification system (activated carbon/molecular sieve/CO absorption layer) with replaceable packing cylinders.

- Pressure maintaining valve to protect filter elements.

| Control and Operation | - PLC microcomputer touch panel for intuitive use.

- Running timer for easy maintenance and management.

- Automatic shutdown, emergency stop, and oil shortage protection functions (optional automatic drain and temperature sequence protection).

- Dual output ports, simultaneously filling two gas cylinders.

- Shockproof pressure gauge (psi/bar dual scale).

| Service and Support | - Third-party authoritative testing reports are available.

- Technical filing for bidding is supported.

- Professional OEM services are provided.

- Customized voltage, frequency, and optional functions are available upon request.

Firefighting breathing air supply: Provides on-site emergency air replenishment for fire stations and fire trucks, ensuring that firefighters have safe and reliable breathing air in toxic and oxygen-deficient environments.

Diving and surface operations: Suitable for diving clubs, maritime rescue, underwater engineering, ship repair, aquaculture and other fields, providing life support air for divers.

Industrial air tightness testing: Used for air tightness testing, pressure resistance testing, and safety valve calibration of products such as high-pressure gas cylinders, valves, pipelines, automotive parts, aviation hoses, and oil tools.

Other applications requiring high-pressure, pure air include: laboratories, medical equipment gas supply, and special processes.

A Chinese manufacturing hub, sincerely inviting global partners to join hands for mutual benefit!

We are actively building a global distribution and service system, and warmly welcome distributors, wholesalers, system integrators and industry partners from all regions to join us in jointly developing the high-pressure breathing air and specialty gas compression market.

We offer you:

OEM/ODM services: We support private label manufacturing and can customize product appearance, logo and packaging according to your brand requirements.

Market customization: Flexible adjustment of product specifications, such as voltage (110V-480V), frequency (50/60Hz), pressure unit (psi/bar), etc., to adapt to the standards of different countries and regions.

Optional upgrade features: Offers value-added options such as automatic sewage control system and remote monitoring module to meet diverse needs.

Comprehensive marketing support: We provide product technical information, testing certificates, promotional materials, and competitive pricing to help with market promotion.

Reliable technical support: A professional engineering team provides pre-sales consultation, installation guidance, and after-sales technical support.

Why choose us?

Quality Cornerstone: Over a decade of market validation and a rigorous quality control system ensure product reliability and durability.

Price competitiveness: Factory direct supply, no middlemen, leaving you with a highly attractive profit margin.

Flexibility in cooperation: From product customization to business models, we are committed to providing cooperation solutions that best suit your needs.

Continuous support: We view our partners as long-term business partners and are committed to growing and developing together.

Contact us now to explore collaboration opportunities and create a better future together!