-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

![[list:title]](https://www.hc986.com/static/upload/image/20251212/1765506806189284.jpg)

Product Overview

The MCH18/SH gasoline engine-driven breathing air compressor is a high-performance, three-stage, high-pressure breathing air compressor designed for critical ap···

Product Overview

The MCH18/SH gasoline engine-driven breathing air compressor is a high-performance, three-stage, high-pressure breathing air compressor designed for critical applications requiring safe, clean, and reliable breathing air. Manufactured to stringent international breathing air standards, it is a reliable choice for firefighting, diving, and industrial safety operations worldwide. With its robust construction, advanced filtration system, and flexible configuration, the MCH18/SH delivers high efficiency and durability in the most demanding environments.

| parameter | Specification |

|---|---|

| model | MCH18/SH |

| Displacement (liters/minute) | 300 |

| Exhaust pressure (bar) | 225 / 330 (optional) |

| Compression levels | Level 3 |

| driving method | gasoline engine |

| Rated speed (rpm) | 1650 |

| Power (kilowatts) | 5.5 |

| Horsepower (hp) | 7.5 |

| Weight (kg) | 127 |

| Dimensions (cm) | 95 (length) × 48 (width) × 65 (height) |

| Gas supply interface | G5/8 × 2 |

| Control method | Automatic shutdown |

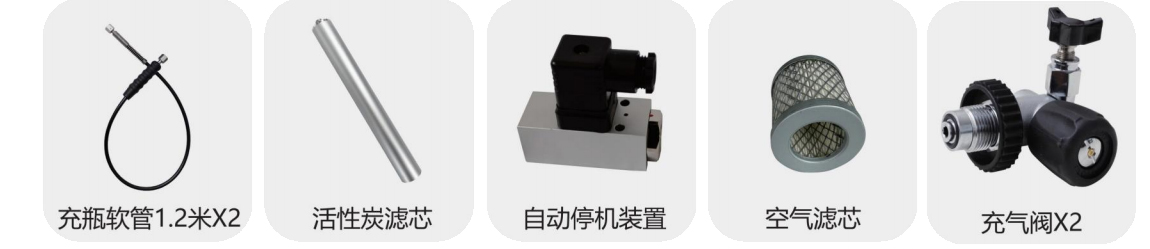

Standard configuration (included with the machine)

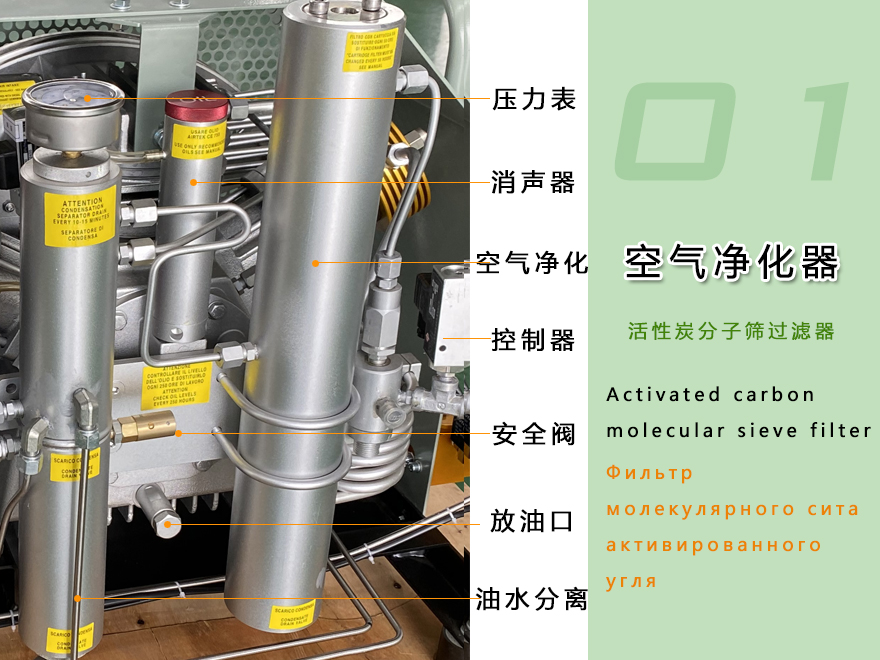

1. Excellent air quality and safety compliance

Air output meets and exceeds international standards for breathing air for diving (EN 12021) and fire fighting (NFPA 1989).

The complete three-stage air purification system includes an oil-water separator, activated carbon, molecular sieves, and carbon monoxide absorbent, ensuring clean, odorless, safe, and reliable air.

Pressure maintaining valves can extend filter life and maintain stable output.

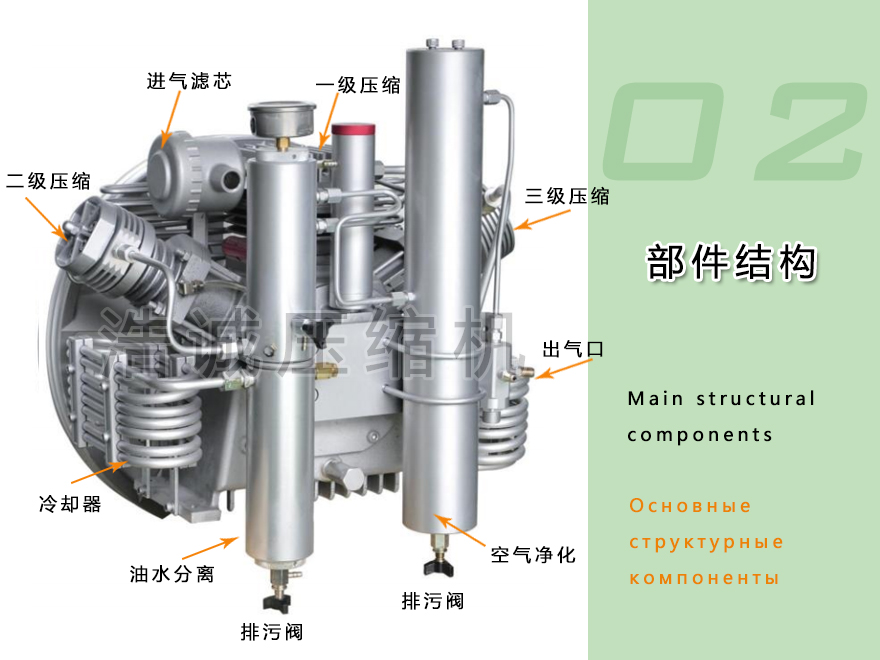

2. Robust and reliable engineering design

The three-cylinder, three-stage compression design ensures efficient and stable high-pressure air output.

The stainless steel cooling system and high-strength nylon cooling fan provide excellent heat dissipation and support long-term operation.

Splash lubrication system ensures efficient cooling and long component life.

3. Advanced protection and operational safety

The motor has overload, overheat and undervoltage protection functions.

Each stage is equipped with a safety valve that automatically releases pressure in case of overpressure, ensuring safety.

The protective covers for rotating parts and the robust and precise base design enhance operator safety.

Shockproof pressure gauge (0-5800 PSI / 400 Bar).

4. User-friendly and intelligent design

Two G5/8 output ports allow for simultaneous filling of two gas cylinders.

The air intake paper filter protects the compressor from dust.

The condenser separator is equipped with a manual drain valve for easy maintenance.

5. Flexibility and Customization Services

Selectable output pressure: 225 bar or 330 bar.

Voltage/frequency customization: Available according to different national or regional standards.

An optional PLC control system can be added to achieve automated operation.

OEM/ODM services: We can provide private label manufacturing and brand customization.

1. Essential equipment for fire and emergency rescue

brigade gas supply stations and various fire trucks. Provides high-quality breathing air for firefighters and rescue personnel in hazardous environments such as dense smoke, toxic gases, or oxygen deficiency at fire scenes, ensuring the safety of firefighting, rescue, and medical operations.

2. Diving and underwater operations

are suitable for diving clubs, commercial diving, marine aquaculture, underwater engineering, ship repair, sunken object salvage, and fishing. It provides divers with safe, purified breathing air and supports recreational, commercial, and industrial underwater activities.

3. Industrial testing and safety applications

are widely used for pressure testing and airtightness inspection, such as for pressure vessels, high-pressure gas cylinders, valves, pipelines, automotive parts, aviation hoses, and precision instruments. They are also used for safety valve calibration and non-destructive testing to ensure equipment integrity and eliminate safety hazards.

| Main applications: diving breathing apparatus, firefighting breathing apparatus, high-pressure gas supply, airtightness testing, airtightness inspection, pipeline pressure testing, etc. |

|

Global investment promotion and cooperation

We are actively expanding our global sales network and sincerely invite distributors, wholesalers and industry partners from all regions to join us in promoting safety and reliability.

Our cooperation support includes:

OEM/Private Label Service: Professional OEM support, customizing product appearance and packaging according to your brand needs.

Customized services: Providing customized solutions for specific voltage, frequency, and regulatory standards of the target market.

Optional upgrades: Options include an enhanced automatic control system to meet diverse operational needs.

Why choose to cooperate with us?

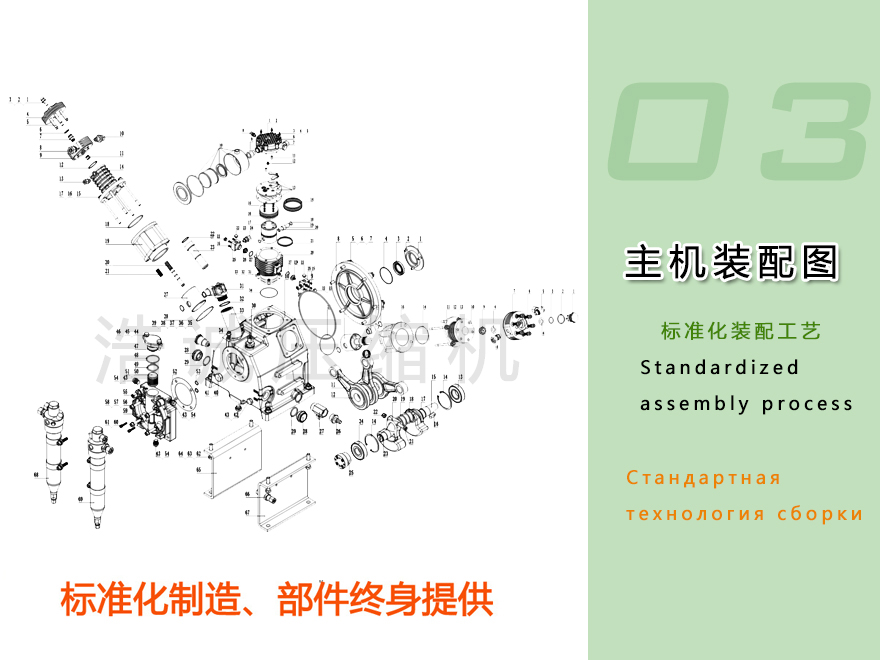

Quality Assurance: A rigorous quality control system ensures that the products are robust and durable.

Highly competitive pricing: Factory direct supply, providing partners with excellent profit margins.

Technical support: Backed by a professional team of engineers and customer service representatives.